Reliable and Efficient 12 Tonne Cable Drum Stand

Engineered for Heavy-Duty Cable Handling

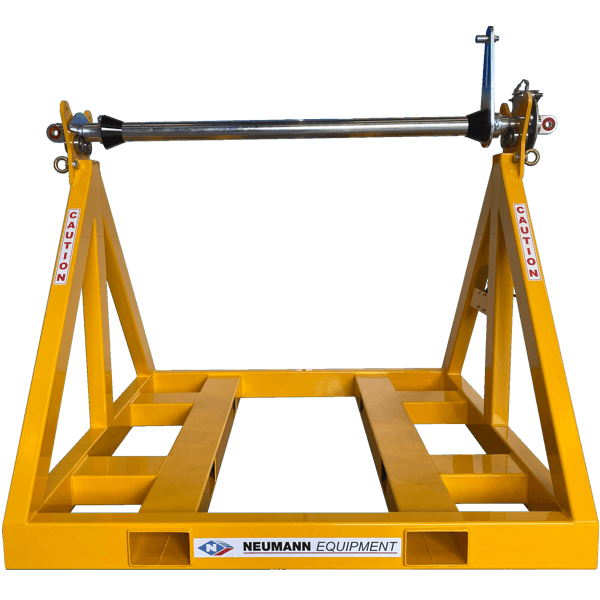

Welcome to the realm of dependable and robust cable handling with Neumann Equipment’s 12,000kg cable drum stand. Crafted to meet the rigorous demands of heavy-duty industrial applications, this formidable solution redefines your cable handling experience. Let us delve into what sets our cable drum stand apart as the ultimate choice.

Unparalleled Design and Specifications

Engineered with meticulous attention to detail, our cable drum stand boasts a maximum weight capacity of 12,000kg, making it exquisitely suited for tackling robust cable operations. Standing tall with a spindle height of 1,828mm and an impressive maximum drum diameter of 3,350mm, it stands prepared to conquer your most formidable challenges.

Engineered for Durability and Strength

At Neumann Equipment, we understand the importance of long-lasting performance. That’s why our cable drum stand is meticulously crafted with a fully welded construction, guaranteeing unmatched strength and reliability. Its innovative two-way forked base design provides exceptional stability and support for seamless cable handling operations. To further prioritise safety, you have the option to include a bolt-on brake assembly, ensuring secure and controlled cable management.

Exemplary Commitment to Quality Assurance

Our unwavering commitment to quality is a cornerstone of Neumann Equipment. To ensure compliance with industry standards, our cable drum stand designs undergo comprehensive verification using Finite Element Analysis (FEA). Every unit is meticulously manufactured and rigorously tested, guaranteeing unrivalled resilience and durability, withstanding the most challenging industrial environments.

Longevity Meets Performance

Neumann Equipment’s cable drum stands are engineered to endure the test of time. With unwavering reliability, you can depend on consistent performance year after year. We fully comprehend the demanding nature of heavy-duty applications, and our cable drum stands are designed to thrive in such environments, ensuring uninterrupted productivity.

Your Trusted Cable Handling Solution

When it comes to heavy-duty cable handling, Neumann Equipment’s 12,000kg cable drum stand stands as the definitive choice. Meticulously crafted with fully welded construction, a steadfast forked base, and the optional bolt-on brake assembly, no detail is overlooked in providing a secure and reliable solution. Our adherence to industry standards and unwavering commitment to durability establishes our cable drum stand as your esteemed ally.

Embrace the Difference Today

Settle for nothing short of excellence in cable handling equipment. Reach out to Neumann Equipment without delay to discuss your unique requirements and explore the transformative potential of our 12,000kg cable drum stand in revolutionising your heavy-duty cable operations. Engage with us today and unlock a world of dependability, resilience, and superior cable handling performance.

CDST-X120

12,000kg Cable Drum Stand

See Other Cable Drum Stands

Standard Inclusions:

- Fully fabricated construction,

- 2-Pac epoxy industrial coating,

- Design verified using Finite Element Analysis (FEA),

- Manufactured to meet industry standards,

- 100mm diameter zinc-plated carbon steel spindle with lifting points,

- The spindle rotates on sealed bearings,

- Zinc-plated torque arm,

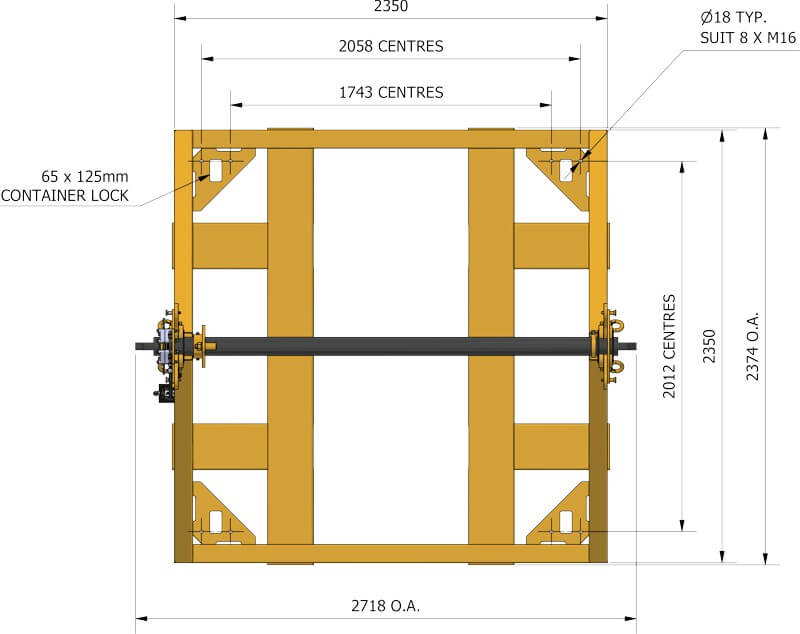

- Front and side forklift tyne pockets, ie. can be lifted from any side,

- The base has four lifting lugs rated to lift the loaded spindle and four tie-down lugs,

- Provisioned for mounting using container locks,

- 8 X Ø18 base mount holes.

Available Options:

- 400 kg hydraulic brake assembly kit includes stainless steel brake disc, callipers and hand pump,

- Spindle cones,

- Certified lifting beam.

Relevant Design Codes:

- AS 3990 – Mechanical Equipment – Steelwork,

- National Transport Commission – NTC Load Restraint Guide – 2018,

- AS 1789 – Electroplated Zinc (Electrogalvanised) Coatings on Ferrous Articles (Batch Process),

- AS 1554.1:2001 – Structural Steel Welding.

Notes:

- The Cable Drum Stand design can be customised to suit your requirements,

- Refer to our range of fabricated Cable Drum Stands for additional features.

Specifications - 12,000 kg Cable Drum Stand

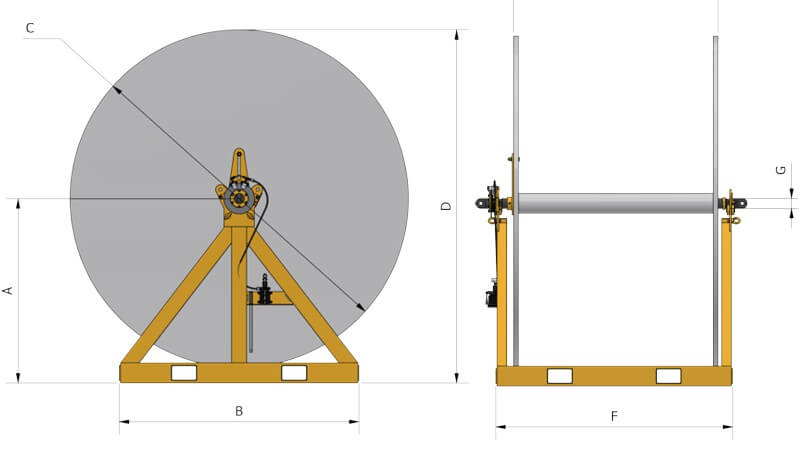

| Model Number | CDST-X1200 |

|---|---|

| Type (Bolted or Fabricated) | Fabricated |

| Maximum Capacity | 12,000 kg |

| Spindle Height (A) | 1,828 mm |

| Drum Stand Width (B) | 1,828 mm |

| Maximum Drum Diameter (C) | 3,350 mm |

| Overall Height (D) | 3,503 mm |

| Maximum Drum Width (E) | 2,050 mm |

| Overall Length (F) | 2,374 mm |

| Spindle Diameter (G) | 100 mm |

| Maximum Brake tension @ 1m Dia. | 400 kg |

| Mass of Frame excluding Drum and Spindle | 650 kg |

Call or email us today to discuss your specific Cable Drum Stand requirements

12 Tonne Cable Drum Stand Image Gallery:

At Neumann Equipment, we aim to provide you with the best product to suit your needs. Please note that the images, drawings, and specifications displayed for this product are only indicative and may not represent the current models or configurations. We continually strive to improve our range of products and reserve the right to change the designs and specifications as new models are developed. Contact our expert sales and customer service team to discuss your requirements and find the best product.

The 12 Tonne Cable Drum Stand has a maximum weight capacity of 12,000kg, making it ideal for heavy-duty cable handling operations. Its impressive weight capacity ensures it can easily handle even the most robust cables and large cable drums, providing reliable support for efficient cable management.

The cable drum stand features a two-way forked base design, providing exceptional stability and support during cable handling operations. This innovative design ensures optimal balance and minimises the risk of tipping or instability, making it suitable for various environments. Additionally, the stand offers versatile mounting options, including provision for mounting using container locks and eight base mount holes. These options allow for secure and flexible installation, whether it’s on a flat surface or within a container or transport vehicle. With multiple mounting possibilities, the cable drum stand can be easily positioned and secured according to specific job site requirements, enhancing stability and ensuring safe and efficient cable handling.

Absolutely! The cable drum stand is constructed with a fully welded design, ensuring optimal strength, longevity, and reliability. Each component is carefully fabricated and welded to withstand the demanding conditions of industrial environments, guaranteeing years of dependable performance and minimising the need for frequent maintenance or replacement. Furthermore, the stand is meticulously painted to provide added durability and corrosion resistance. It is coated with a high-quality 2-Pac epoxy industrial coating, which forms a protective barrier against environmental elements, such as moisture and UV radiation. This robust painting ensures that the cable drum stand maintains its integrity and appearance, even in harsh operating conditions, making it a reliable choice for long-term cable handling operations.

Yes, the stand is designed to handle large cable drums with a maximum diameter of 3,350mm and a maximum width of 2,050mm, allowing for efficient cable handling. Whether you’re dealing with oversized cables or extensive cable lengths, the 12 Tonne Cable Drum Stand provides ample space and support for hassle-free cable management. Its generous drum width capacity ensures compatibility with a wide range of cable sizes, offering versatility and adaptability for different applications. With the ability to accommodate large cable drums, the stand enables seamless unwinding and winding processes, saving time and effort while maintaining optimal cable tension.

For enhanced safety, the cable drum stand offers the option to include a bolt-on brake assembly, ensuring secure and controlled cable management. This optional feature provides additional control during cable operations, allowing operators to safely regulate the speed and tension of cable unwinding and winding processes, reducing the risk of accidents and damage to equipment.

Yes, the design of the cable drum stand undergoes comprehensive verification using Finite Element Analysis (FEA) to ensure compliance with industry standards. Neumann Equipment is committed to adhering to relevant design codes and regulations, including AS 3990, NTC Load Restraint Guide, AS 1789, and AS 1554.1:2001. This dedication to compliance guarantees that the cable drum stand meets the necessary safety, performance, and structural integrity requirements.

Absolutely. The cable drum stand is meticulously manufactured and rigorously tested to withstand the most challenging industrial environments, guaranteeing unrivalled resilience and durability. It is not only built to handle heavy loads but also designed to withstand harsh conditions. One of the key features contributing to its durability is the high-quality paint coating. The cable drum stand undergoes a meticulous painting process, ensuring optimal protection against corrosion and environmental factors. It is coated with a durable and high-performance 2-Pac epoxy industrial coating, which provides a robust barrier against moisture, chemicals, and UV radiation. This advanced paint coating enhances the stand’s longevity and helps maintain its appearance over time, making it a reliable choice for demanding industrial applications.

Yes, Neumann Equipment offers customisation options to tailor the cable drum stand to meet specific requirements, ensuring it fits perfectly into your cable handling operations. Our team understands that every project has unique needs, and we are dedicated to providing personalised solutions. From custom sizes and additional features to specific finishes or branding, we work closely with our customers to deliver a cable drum stand that perfectly aligns with their individual requirements.

Yes, the 12 Tonne Cable Drum Stand includes a zinc-plated torque arm as a standard inclusion. This torque arm helps prevent cable drum slippage during unwinding and winding operations, providing additional security and control. It ensures that the cable drum remains stable and in position, minimising the risk of accidents or cable entanglement.

Absolutely. At Neumann Equipment, we understand that each project has unique needs. Therefore, we offer customisation options for the cable drum stand to tailor to specific requirements. Whether it’s custom dimensions, additional features, or particular finishes, we work closely with our customers to provide personalised solutions. Our team of experts will collaborate to ensure that the cable drum stand meets your exact specifications, making it an ideal fit for your cable handling operations.

Looking for high-quality cable drum stands to meet your requirements? Look no further than Neumann Equipment! Our extensive range of cable drum stands is designed to provide practical solutions for clients around the globe.

Need something custom-designed? We can do that too! Contact our experienced team today to discuss your needs and find the perfect cable drum stand for you.

At Neumann Equipment, we take pride in designing and engineering high-quality cable reel stands built to last. Our in-house mechanical engineers utilise FEA computer modelling software to create robust and reliable products that meet industry standards.

When you purchase a cable reel stand from us, you can trust that it has undergone rigorous testing and meets our strict quality control measures. Our Quality Assurance Systems fully comply with AS/NZS ISO 9001:2008, ensuring that every unit is manufactured to the highest standards.

All of our cable reel stands are designed and manufactured at our Currumbin facility on the beautiful Gold Coast of Queensland, Australia. We are proud to be an Australian-owned and operated company providing practical solutions to clients all around the globe.

If you’re in the market for cable handling equipment, look no further than Neumann Equipment. We offer a range of options, including custom-designed stands to meet your specific needs. Contact our experienced Sales, Service, and Spare Parts team to discuss your requirements and find the perfect solution for your business.

Articles about 12,000kg Standard Duty Cable Drum Stands:

The manufacturing process for a 12,000kg Standard-Duty Cable Drum Stand at Neumann Equipment involves various stages, from design and engineering to fabrication and testing. This essay will provide a detailed overview of each step in the process, highlighting the expertise and attention to detail that goes into each unit.

Design and Engineering

The first step in the manufacturing process is designing and engineering the cable drum stand. Neumann Equipment has an in-house team of qualified mechanical engineers who use Finite Element Analysis (FEA) computer modelling software to verify the design. The engineers consider the stand’s weight capacity, compatibility with cable drum sizes, and the drum’s maximum width and diameter. They also factor in industry standards and regulations to ensure the stand’s safety and durability.

Fabrication

Once the design has been verified, the fabrication process begins. The fabrication team at Neumann Equipment uses state-of-the-art equipment and machinery to cut, shape, and weld the components of the cable drum stand. The fabrication team follows strict quality control procedures to ensure the stand is manufactured to the highest standards.

Testing

Before the cable drum stand is dispatched, it undergoes rigorous testing to ensure it meets the required weight capacity and safety standards. The testing process involves placing a maximum size and weight cable drum onto the stand and assessing its performance under load. If the stand passes the test, it is ready for dispatch to the customer.

Delivery

Once the cable drum stand has passed the testing process, it is packaged and prepared for delivery. The packaging team at Neumann Equipment takes excellent care to protect the stand during transportation. The stand is then delivered to the customer’s location, which can be used in the field.

Conclusion

Neumann Equipment takes great pride in its manufacturing process for cable drum stands. Each unit undergoes rigorous design and engineering, fabrication, and testing to ensure that it meets the highest safety, durability, and performance standards. Customers can trust Neumann Equipment to provide them with a high-quality, reliable cable drum stand that will meet their needs in the field. If you are in the market for industrial equipment, contact the experienced sales and customer service team at Neumann Equipment to discuss your cable handling requirements.

Neumann Equipment is a company that prides itself on designing and manufacturing high-quality cable-handling equipment. Their 12,000kg Standard-Duty Cable Drum Stand is their flagship product, providing exceptional durability and functionality. In this essay, we will delve into Neumann Equipment’s 12,000kg Standard-Duty Cable Drum Stand’s process, from concept to delivery.

Concept and Design:

The concept and design phase is the first step in creating the 12,000kg Standard-Duty Cable Drum Stand. This is where Neumann Equipment’s team of experienced mechanical engineers gather and brainstorm ideas, develop designs, and create 3D computer models using Finite Element Analysis (FEA) software. These models allow them to simulate real-world stresses and strains on the equipment, ensuring it can withstand the extreme conditions it will encounter on the job.

Prototyping and Testing:

Once the design is finalised, it’s time to create a prototype. Neumann Equipment’s skilled technicians bring the design to life, producing the first 12,000kg Standard-Duty Cable Drum Stand. This prototype is tested rigorously to meet the company’s quality standards.

Manufacturing:

Once the prototype passes testing, the manufacturing process begins. Neumann Equipment’s state-of-the-art facility in Currumbin, Queensland, becomes a hive of activity as the team sets to work. Each component is carefully manufactured, following strict quality control standards to ensure the highest precision and accuracy. The equipment is fabricated from high-quality steel with a hot-dip galvanised finish with excellent corrosion resistance.

Assembly and Painting:

The next stage involves assembling all the components into the final product. The team at Neumann Equipment takes excellent care to ensure that all parts are fitted precisely, providing the equipment is sturdy and reliable when in use. Once the assembly is complete, the 12,000kg Standard-Duty Cable Drum Stand is painted in Neumann Equipment’s signature blue, providing a long-lasting and durable finish.

Quality Assurance:

Quality assurance is critical in the process, ensuring that each 12,000kg Standard-Duty Cable Drum Stand meets Neumann Equipment’s exacting standards. Every piece of cable handling equipment is thoroughly inspected and undergoes a battery of tests to ensure it meets the stringent quality control requirements.

Dispatch:

Once the quality assurance process is complete, the equipment is carefully packaged and dispatched. Neumann Equipment’s experienced logistics team ensures that each piece of equipment is delivered on time and in perfect condition, ready to be put to work by the customer.

Conclusion:

Creating Neumann Equipment’s 12,000kg Standard-Duty Cable Drum Stand is a comprehensive process involving a team of skilled mechanical engineers, technicians, and quality control experts. Each process step is carefully planned and executed from the initial concept and design stage to the final dispatch. The result is an exceptional piece of cable handling equipment built to last, providing the highest level of performance and reliability for those needing a heavy-duty cable drum stand.

Elevate Your Cable Handling with the Power of a 12 Tonne Cable Drum Stand

The 12-tonne cable drum stand by Neumann Equipment is a robust and reliable solution for heavy-duty cable handling applications. This essay aims to provide a detailed exploration of its features, focusing on the standard inclusions and available options. Additionally, it will delve into the relevant design codes that ensure compliance with industry standards.

Standard Inclusions:

- Fully Fabricated Construction: The cable drum stand boasts a fully welded construction, guaranteeing maximum strength and durability. This ensures its ability to withstand the demanding conditions of industrial applications.

- 2-Pac Epoxy Industrial Coating: To protect against corrosion and wear, the stand is coated with a 2-Pac epoxy industrial coating. This provides an added layer of longevity and resilience.

- Design Verified Using Finite Element Analysis (FEA): Neumann Equipment employs advanced engineering techniques, including Finite Element Analysis, to verify the design of the cable drum stand. This ensures that it meets stringent industry standards for safety and performance.

- Manufactured to Meet Industry Standards: The stand is meticulously manufactured to meet industry standards, guaranteeing its reliability and compatibility with a wide range of heavy-duty cable handling operations.

- 100mm Diameter Zinc-Plated Carbon Steel Spindle with Lifting Points: The cable drum stand features a 100mm diameter spindle made of zinc-plated carbon steel. This robust spindle, equipped with lifting points, facilitates secure and efficient cable handling.

- Sealed Bearing Spindle Rotation: The spindle rotates on sealed bearings, minimizing friction and enabling smooth rotation during cable unwinding and winding processes.

- Zinc-Plated Torque Arm: Including a zinc-plated torque arm enhances stability and control during cable handling operations, contributing to safe and reliable performance.

- Forklift Tyne Pockets: Conveniently located front and side forklift tyne pockets allow for easy transportation and positioning of the cable drum stand.

- Lifting and Tie-Down Lugs: The base of the stand is equipped with four lifting lugs specifically designed to lift the loaded spindle, as well as four tie-down lugs for added security during transportation.

- Provision for Mounting Using Container Locks: The cable drum stand is provisioned for mounting using container locks, ensuring stability and security during transport and storage.

- Eight Base Mount Holes: The stand features eight Ø18 base mount holes, offering versatility in installation and adaptability to various environments.

Available Options:

- 400 kg Hydraulic Brake Assembly Kit: This optional kit includes a stainless steel brake disc, callipers, and a hand pump. It provides enhanced braking capabilities, ensuring safe and controlled cable handling operations.

- Spindle Cones: Spindle cones are available as an option, providing additional support and stability when handling large cable drums.

- Certified Lifting Beam: The inclusion of a certified lifting beam provides a secure and efficient means of lifting the cable drum stand, facilitating safe and hassle-free transportation.

Relevant Design Codes:

- AS 3990 – Mechanical Equipment – Steelwork: This design code outlines the requirements and standards for steelwork used in mechanical equipment; it ensures that the cable drum stand’s steel components meet the necessary criteria for structural integrity and safety.

- National Transport Commission (NTC) Load Restraint Guide – 2018: The NTC Load Restraint Guide specifies the guidelines for secure load restraint during transportation. This guide ensures the cable drum stand is safely secured and properly restrained during transit.

- AS 1789 – Electroplated Zinc (Electrogalvanised) Coatings on Ferrous Articles (Batch Process): AS 1789 establishes the standards for electroplated zinc coatings on ferrous articles. This code ensures that the zinc-plated components of the cable drum stand meet the required quality and durability standards, providing protection against corrosion and extending the product’s lifespan.

- AS 1554.1:2001 – Structural Steel Welding: AS 1554.1:2001 sets forth the guidelines for structural steel welding. Compliance with this code ensures that the welding processes used in fabricating the cable drum stand meet the necessary quality and structural integrity standards.

By adhering to these relevant design codes, Neumann Equipment ensures that the 12-tonne cable drum stand meets industry safety, performance, and durability standards. This commitment to compliance underscores the company’s dedication to delivering a high-quality product that meets the rigorous demands of heavy-duty cable handling applications.

Conclusion:

The 12-tonne cable drum stand by Neumann Equipment is a robust, reliable solution for heavy-duty cable handling operations. Its standard inclusions, such as the fully fabricated construction, 2-Pac epoxy industrial coating, and zinc-plated carbon steel spindle, ensure durability, efficiency, and ease of use. The available options, including the hydraulic brake assembly kit, spindle cones, and certified lifting beam, provide added flexibility and customization for specific requirements. Furthermore, compliance with design codes such as AS 3990, NTC Load Restraint Guide, AS 1789, and AS 1554.1:2001 guarantees that the cable drum stand meets industry standards for safety, structural integrity, and corrosion resistance.

Neumann Equipment’s commitment to delivering a high-quality product that withstands the harshest industrial conditions is evident in its meticulous design and manufacturing processes. The 12-tonne cable drum stand is not only built to last but also built to perform reliably and consistently throughout its lifespan. Whether for large-scale construction projects, mining operations, or industrial installations, the cable drum stand is an indispensable tool for efficient and secure cable handling.

In conclusion, Neumann Equipment’s 12-tonne cable drum stand is a testament to its expertise and dedication to providing reliable, durable, high-performance solutions for heavy-duty cable handling. It offers a robust and efficient solution for various industrial applications with a comprehensive range of features, customizable options, and adherence to relevant design codes.

Are you ready to take your cable handling to the next level? Embrace the unmatched strength and reliability of the 12T cable drum stand from Neumann Equipment. With its robust construction, versatile features, and adherence to industry standards, it’s the perfect solution for heavy-duty cable operations. Don’t miss out on the opportunity to enhance your productivity and efficiency.

Contact us today to discuss your requirements and discover how the 12T cable drum stand can revolutionize your cable handling processes. Elevate your operations and experience the power of a 12T Cable Drum Stand with Neumann Equipment.

Power Up Your Cable Handling with the 12-Tonne Drum Stand!

The 12-tonne cable drum stand by Neumann Equipment is an exceptional solution designed to revolutionise heavy-duty cable handling operations. This comprehensive article will review its specifications, highlighting its benefits for efficient and reliable cable handling.

Impressive Specifications:

The 12-tonne cable drum stand has been meticulously engineered to excel in demanding cable handling applications. Let’s explore its impressive specifications:

- Maximum Weight Capacity: With a robust design, this cable drum stand can handle an impressive maximum weight capacity of 12 tonnes. It ensures optimal performance when dealing with heavy cables, providing unmatched reliability and efficiency.

- Spindle Height: Standing at 1,828mm, the cable drum stand offers ample clearance for accommodating large cable drums, streamlining the cable handling process and ensuring easy manoeuvrability.

- Drum Stand Width: With a width of 2,374mm, the cable drum stand provides stability and balance during cable unwinding and winding operations. Its wide structure minimises the risk of cable entanglement and enhances safety.

- Maximum Drum Diameter: The cable drum stand accommodates drums with a maximum diameter of 3,350mm. This generous size allows for the seamless handling of larger cable drums, saving valuable time and effort.

- Overall Height: Reaching a height of 3,503mm, the cable drum stand enables ergonomic cable handling and facilitates smooth operations, reducing strain and improving productivity.

- Maximum Drum Width: With a capacity to handle drums up to 2,050mm in width, this cable drum stand ensures compatibility with a wide range of cable sizes, offering versatility and adaptability.

- Overall Length: The cable drum stand measures 2,374mm in length, providing a compact and well-balanced structure that optimises space utilisation and facilitates easy transportation.

- Spindle Diameter: Equipped with a sturdy 100mm diameter spindle, this cable drum stand ensures secure and stable cable handling. The spindle’s reliable design guarantees efficient rotation, facilitating smooth unwinding and winding processes.

Benefits of Cable Handling:

The 12-tonne cable drum stand offers numerous advantages that enhance cable handling operations. Let’s explore its key benefits:

- Enhanced Stability and Safety: The fully welded construction and robust design of the cable drum stand provide exceptional stability, minimising the risk of accidents and ensuring safe and secure cable handling. Its forked base design further enhances stability and support during operations.

- Efficient Cable Handling: The generous weight capacity and dimensions of the cable drum stand enable efficient handling of heavy cables and large cable drums. It simplifies the process, saving time and effort while ensuring smooth cable unwinding and winding.

- Durability for Demanding Environments: Constructed with longevity in mind, the cable drum stand is built to withstand harsh industrial conditions. Its fully welded construction, combined with a 2-Pac epoxy industrial coating, ensures durability and corrosion resistance, extending the product’s lifespan.

- Versatility and Adaptability: The cable drum stand’s compatibility with various drum sizes, widths, and weights makes it versatile for diverse cable handling requirements. Its provision for mounting using container locks and multiple base mount holes adds further adaptability for different environments.

Conclusion:

The 12-tonne cable drum stand by Neumann Equipment is a powerhouse solution designed to elevate cable handling operations to new heights. With its impressive specifications, including maximum weight capacity, spindle height, and drum dimensions, it offers unmatched efficiency and reliability. The benefits it brings, such as enhanced stability, efficient cable handling, durability, and adaptability, make it an invaluable asset for heavy-duty cable operations.

Experience the difference of the 12-tonne cable drum stand today and elevate your cable handling capabilities to new heights. Embrace its efficiency and strength, enabling seamless operations and enhanced productivity.

Ensure safe and secure cable handling with the stand’s robust construction and stable design. Its generous weight capacity and dimensions allow for efficient handling of heavy cables and large drums, reducing time and effort. Experience peace of mind knowing that the cable drum stand is built to withstand harsh industrial conditions, offering durability and corrosion resistance.

The versatility and adaptability of the cable drum stand make it suitable for a wide range of cable handling requirements. Its provision for mounting using container locks and multiple base mount holes ensures easy installation in diverse environments. It is a reliable solution that adapts to your specific needs.

Invest in the 12-tonne cable drum stand and unlock its potential for optimal cable handling operations. Whether you’re in construction, mining, or industrial installations, this stand will be an indispensable tool in streamlining your cable handling processes.

Don’t miss out on the opportunity to experience the efficiency and strength of the 12-tonne cable drum stand.

Contact Neumann Equipment today to discuss your requirements and explore how this stand can elevate your cable-handling operations.

Discover a new reliability, durability, and performance level with the 12-tonne cable drum stand and take your cable handling to new heights.

Strength and Precision Redefined: Neumann Equipment’s 12-Tonne Cable Drum Stand, Engineered for Excellence.

Neumann Equipment proudly presents the 12 Tonne Cable Drum Stand, an innovative solution designed to revolutionise heavy-duty cable handling operations. In this promotional article, we will highlight the standout standard inclusions of this stand and the remarkable hydraulic brake option. Discover how these features combine to deliver unmatched performance and safety in cable handling.

Section 1: Standard Inclusions for Enhanced Efficiency and Durability

At Neumann Equipment, we prioritise delivering exceptional value to our customers. The 12 Tonne Cable Drum Stand comes equipped with several standard inclusions that maximise efficiency and ensure long-lasting durability. These include:

- Fully fabricated construction: The 12 Tonne Cable Drum Stand boasts a fully fabricated construction that showcases superior craftsmanship and attention to detail. Every component is carefully designed and precision-engineered, ensuring exceptional strength and durability. The stand is meticulously constructed using high-quality materials and advanced manufacturing techniques, guaranteeing a robust and reliable structure that can withstand the rigours of heavy-duty cable handling operations.

- 2-Pac epoxy industrial coating: To provide unparalleled protection against corrosion, wear, and environmental factors, the stand is coated with a 2-Pac epoxy industrial coating. This specialised coating creates a resilient barrier that shields the stand from harsh conditions, such as moisture, chemicals, and UV exposure. The coating enhances the stand’s longevity, ensures easy maintenance, and preserves its aesthetic appeal over time.

- Design verified using Finite Element Analysis (FEA): The 12 Tonne Cable Drum Stand design is rigorously verified using advanced Finite Element Analysis (FEA) techniques. FEA allows engineers to simulate and evaluate the stand’s structural behaviour under various loads and conditions. Through comprehensive analysis, any potential weaknesses or areas of improvement are identified and addressed, ensuring that the stand meets and exceeds industry standards for safety, performance, and reliability.

- Manufactured to meet industry standards: Neumann Equipment takes pride in manufacturing the 12 Tonne Cable Drum Stand to meet and surpass industry standards. Every step of the manufacturing process adheres to stringent quality control measures, ensuring the final product is of the highest standard. By meeting industry standards, the stand guarantees superior performance, reliability, and compliance with safety regulations, providing peace of mind to operators and users.

- 100mm diameter zinc-plated carbon steel spindle with lifting points:

The stand features a robust 100mm diameter zinc-plated carbon steel spindle with lifting points designed to securely hold and lift heavy cable drums. The zinc plating enhances the spindle’s corrosion resistance and longevity, ensuring optimal performance and ease of use. The lifting points provide convenient attachment points for lifting equipment, facilitating safe and efficient cable-handling operations. - The spindle rotates on sealed bearings: The stand incorporates sealed bearings in the spindle assembly, enabling smooth and frictionless rotation. This design feature reduces operational resistance and ensures seamless unwinding and winding of cables. The sealed bearings enhance the stand’s performance and longevity by minimising wear and tear.

- Zinc-plated torque arm: The stand is equipped with a zinc-plated torque arm to provide added stability and control during cable handling. This feature helps to prevent excessive movement and maintains precise alignment between the spindle and the cable drum. The zinc plating offers corrosion resistance, ensuring the torque arm remains durable and reliable even in challenging environments.

- Front and side forklift tyne pockets: The stand is designed with convenient front and side pockets, facilitating easy transportation and positioning. These pockets allow forklift tynes to slide securely beneath the frame, enabling effortless lifting and movement. This design feature ensures efficient handling and minimises the risk of damage to the stand or surrounding equipment during transportation.

- The base has four lifting lugs rated to lift the loaded spindle and four tie-down lugs: For ease of lifting and secure anchoring, the base of the stand is equipped with four lifting lugs specifically rated to lift the loaded spindle. These lifting lugs provide reliable attachment points for lifting equipment, ensuring safe and efficient handling of the stand. Additionally, the base features four tie-down lugs, allowing for secure fastening and stability during transportation or stationary use.

- Provisioned for mounting using container locks: To enhance versatility and ease of use, the stand is provisioned for mounting using container locks. This feature enables convenient and secure mounting of the stand onto various surfaces or structures, such as flatbed trailers or specialised cable handling equipment. The provision for mounting using container locks ensures stability during transportation, preventing unnecessary movement or shifting that could compromise the safety and integrity of the cable drum stand.

- 8 X Ø18 base mount holes: The base of the stand is equipped with 8 Ø18 base mount holes, providing versatile options for installation and securing the stand to different surfaces. These pre-drilled mount holes offer flexibility in positioning and allow for compatibility with a variety of mounting configurations. Whether bolting the stand to a concrete pad or securing it to a specialised cable handling system, the base mount holes ensure a secure and reliable connection.

Section 2: The Hydraulic Brake Option for Enhanced Safety and Control

We offer an optional hydraulic brake assembly kit to further elevate the performance of the 12 Tonne Cable Drum Stand. This advanced braking system provides additional safety and control during cable handling operations. Key features of the hydraulic brake option include:

Stainless Steel Brake Disc and Calipers: The optional hydraulic brake assembly kit for the 12 Tonne Cable Drum Stand features high-quality stainless steel brake discs and callipers. These components are meticulously designed to withstand heavy-duty usage and provide exceptional durability. The stainless steel construction ensures resistance to corrosion, heat, and wear, ensuring reliable braking performance even in demanding environments. The precision engineering of the brake discs and callipers provides optimal contact and friction, allowing for smooth and controlled braking action during cable handling operations. With the stainless steel brake components, operators can fully believe the stand can halt cable drum rotation precisely and securely, enhancing safety and control.

User-Friendly Hand Pump: The hydraulic brake assembly kit includes a user-friendly hand pump, adding an extra layer of convenience and control to cable handling operations. The hand pump is designed for effortless operation, allowing operators to apply and precisely release brake pressure. With its ergonomic design and intuitive controls, the hand pump ensures operators can easily modulate the braking force according to their specific needs. This level of control enhances safety by allowing for precise adjustments and reducing the risk of sudden stops or abrupt movements during cable handling. The hand pump’s responsive and reliable performance empowers operators to maintain high control and confidence throughout their cable handling tasks, making the entire process more efficient and secure.

Incorporating the hydraulic brake assembly kit into the 12 Tonne Cable Drum Stand amplifies its safety and control features. The stainless steel brake disc and callipers deliver durability and reliable braking performance, ensuring safe and secure cable handling operations. The user-friendly hand pump further enhances safety by providing operators with intuitive control over the braking action, allowing for smooth and precise adjustments as needed. Together, these features contribute to a heightened level of safety, control, and peace of mind during cable handling operations.

Section 3: Promoting Safety and Efficiency with Neumann Equipment

The 12 Tonne Cable Drum Stand by Neumann Equipment embodies our commitment to delivering the highest safety and efficiency standards in heavy-duty cable handling operations. Each aspect of the stand’s design and functionality has been meticulously engineered to ensure optimal performance, operator safety, and seamless cable handling.

- Superior Stability and Control: The fully fabricated construction and precision engineering of the 12 Tonne Cable Drum Stand provide exceptional stability and control during cable handling operations. The stand’s robust structure, carefully designed dimensions, and weight distribution offer a solid foundation for secure cable drum placement. This stability prevents unnecessary movement or shifting that could compromise safety or cause damage to the cables or surrounding equipment. Operators can rely on the stand’s stability and control to maintain precise alignment and minimise any potential risks associated with cable handling.

- Enhanced Maneuverability: Neumann Equipment understands the importance of ease of use and maneuverability in cable handling operations. The stand is equipped with front and side forklift tyne pockets, allowing for convenient transportation and positioning using forklift equipment. These specially designed pockets enable operators to lift and move the stand effortlessly, reducing manual handling and expediting setup and relocation processes. By streamlining the maneuverability of the stand, operators can optimise their time and efforts, enhancing overall efficiency and productivity.

- Versatile Attachment and Mounting Options: The 12 Tonne Cable Drum Stand offers versatile attachment and mounting options to accommodate various cable handling scenarios. The stand features a 100mm diameter zinc-plated carbon steel spindle with lifting points, enabling secure attachment and effortless lifting of heavy cable drums. Additionally, the base of the stand is designed with four lifting lugs rated to lift the loaded spindle and four tie-down lugs for secure fastening during transportation or stationary use. Moreover, the stand is provisioned for mounting using container locks, allowing for flexible installation onto different surfaces or specialised cable handling equipment. These versatile attachment and mounting options ensure compatibility with a wide range of cable handling setups, maximising adaptability and convenience.

- Enhanced Safety Features: Safety is paramount in cable handling operations, and the 12 Tonne Cable Drum Stand incorporates several features to promote a secure working environment. The stand is equipped with a zinc-plated torque arm that provides additional stability and control, minimising any potential risks associated with excessive movement or misalignment. Furthermore, the front and side forklift tyne pockets facilitate safe and secure lifting and positioning, reducing the risk of accidents or injuries during transportation. The base of the stand includes four lifting lugs and four tie-down lugs, ensuring a secure and stable setup during cable handling operations. These safety features prioritise the well-being of operators and contribute to accident prevention and overall operational safety.

In conclusion, the 12 Tonne Cable Drum Stand from Neumann Equipment offers a comprehensive range of features and functionalities that promote safety, efficiency, and versatility in heavy-duty cable handling operations. The superior stability and control, enhanced maneuverability, versatile attachment and mounting options, and the incorporation of enhanced safety features provide operators with a reliable and optimised cable handling solution. Trust in Neumann Equipment’s commitment to excellence and experience the unparalleled safety and efficiency offered by the 12 Tonne Cable Drum Stand.

Don’t miss out on the opportunity to upgrade your cable handling operations with the 12 Tonne Cable Drum Stand from Neumann Equipment. Experience the power of advanced features and enhanced safety with the hydraulic brake option. Contact us today to discuss your requirements and discover how our reliable and innovative solutions can transform your cable handling processes.