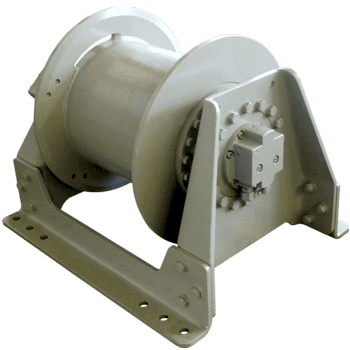

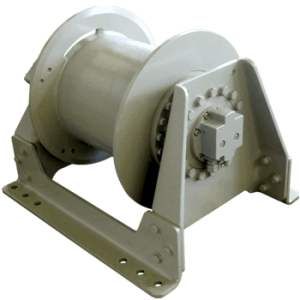

Barge Winches

Unleash the Power of Custom-Made Barge Winches – Tailored Solutions for Your Vessel’s Demands

Are you tired of settling for off-the-shelf barge winches that fall short of meeting your specific needs? At Neumann Equipment, we believe in the power of customisation. Our team of experts takes pride in designing and manufacturing high-quality barge winches that not only adhere to marine industry standards but also cater to the unique requirements of your vessel. Say goodbye to compromise and embrace the advantages of our custom-made barge winches that are built to exceed your expectations.

Superior Performance in Any Marine Environment – Reliability and Durability Redefined

When it comes to barge winches, reliability and durability are paramount. At Neumann Equipment, we understand the challenges posed by marine environmental conditions. That’s why we go above and beyond to deliver high-quality winches that provide years of unwavering service. With our extensive experience and meticulous attention to detail, you can trust our barge winches to withstand the harshest elements and deliver superior performance consistently. Don’t settle for less when you can have the best.

Versatility Beyond Measure – Adaptable to Your Every Barge Application

Versatility is the hallmark of Neumann Equipment’s barge winches. We recognise that different barge applications demand different capabilities. Whether you require lifting and hoisting compliant loading doors and ramps, hauling equipment, precise positioning, or vessel anchoring and securing, our custom-designed winches can adapt seamlessly. With our comprehensive range of features and options, we ensure that our barge winches cater to your unique needs, providing a solution that is both cost-effective and straightforward.

Unlock Cost-Effective Efficiency – Simplify Your Operations with Neumann Equipment’s Barge Winches

In today’s competitive landscape, efficiency is key. Neumann Equipment understands the importance of streamlining your operations without compromising on quality. Our barge winches are designed to deliver cost-effective efficiency, saving time, effort, and resources. With our custom-made solutions, you can experience hassle-free hauling, seamless positioning, and secure anchoring, all while maximising productivity. Trust Neumann Equipment to provide the winching solutions that optimise your operations and set you apart from the competition.

Standard Inclusions:

- Reduction style gearboxes to suit specific vessel requirements,

- Electric or hydraulic drive motors to suit specific applications,

- The barge winch drum is supported with a fully sealed self-aligning outrigger bearing,

- Spring-applied hydraulic/electric release failsafe brake,

- Rope termination clamps to suit steel or Dyneema rope,

- The base and drum are fabricated from carbon steel as standard,

- All components are grit blasted, primed with two-pack epoxy primer, and finished with heavy-duty, two-pack epoxy polyamine marine coatings.

Available Options:

- Line pull capacities – up to 50,000kg,

- Hauling line speeds – up to 100 metres per minute,

- Stainless steel construction,

- Optional dual-purpose winch using the side-mounted gypsy,

- Freewheeling gypsy to deploy the anchor,

- Optional capstan (windlass) waist size – up to 450mm diameter,

- We can cast gypsy and capstan (windlass) heads in either SG iron or manganese bronze,

- Torque-limiting clutches.

Call or email us today to discuss your specific requirements

Barge Winch Image Gallery

At Neumann Equipment, we always look to improve our range of products to offer our customers the best possible solutions for their needs. As a result, we reserve the right to change our designs and specifications as we develop new models.

Please note that the images, drawings, and specifications on our website and marketing materials are indicative only and may not represent the current models or configurations. Don’t hesitate to contact our expert sales and customer service team to ensure you get the most up-to-date and accurate information. They can help you find the perfect barge winch to meet your needs and provide the information required to make an informed decision. So, give us a call today to get started!

A barge winch is a mechanical device designed to handle various operations on barges, such as lifting and hoisting, hauling, positioning, and anchoring. It utilises a drum and rope or cable system to provide the necessary pulling force for these tasks.

Custom-made barge winches offer several advantages over off-the-shelf options. They are specifically tailored to meet the unique requirements of your vessel, ensuring optimal compatibility and performance. Customisation allows for the incorporation of specific features, capacities, and functionalities that may not be available in standard winches, resulting in improved efficiency and effectiveness.

Neumann Equipment prioritises durability using high-quality materials, such as carbon steel and employs advanced construction techniques. To enhance corrosion resistance, the winches undergo meticulous grit blasting, priming, and heavy-duty marine coatings. Their design and manufacturing processes also incorporate structural analysis and simulation to ensure robustness and reliability in challenging marine environments.

Neumann Equipment integrates failsafe brake systems, such as spring-applied hydraulic or electric release mechanisms, to prevent uncontrolled movements and enhance safety. These systems engage automatically in the event of power failure or operator error. Additionally, load monitoring and control mechanisms are available to prevent overloading and ensure safe operations.

Yes, Neumann Equipment’s barge winches are versatile and can be adapted to various barge applications. They can handle tasks such as lifting compliant loading doors and ramps, hauling equipment, precise positioning, and vessel anchoring and securing. The company offers a range of options, capacities, and speeds to accommodate diverse operational requirements.

Neumann Equipment maintains a commitment to quality and compliance. Their internal Quality Assurance Systems align with AS/NZS ISO 9001:2008, ensuring exceptional quality throughout the design and manufacturing processes. They also adhere to relevant marine and industry standards, conducting third-party checks when necessary to validate compliance.

Yes, Neumann Equipment offers comprehensive training programs to equip operators with the necessary knowledge and skills to operate their winches safely and efficiently. Their knowledgeable sales, service, and spare parts team also provides ongoing support to address customers’ questions or concerns.

Yes, Neumann Equipment provides customization options for line pull capacities of up to 50,000kg and hauling line speeds of up to 100 meters per minute. These options allow customers to tailor the winch’s performance to their specific operational requirements.

Neumann Equipment’s barge winches are primarily fabricated from carbon steel as a standard. However, they also offer options for stainless steel construction, which provides enhanced corrosion resistance in corrosive marine environments.

You can contact Neumann Equipment’s knowledgeable Sales, Service, and Spare Parts team for inquiries or to discuss your barge winch requirements. They are available to assist and guide you through choosing the right winch for your needs.

At Neumann Equipment, we take pride in delivering high-quality barge winches designed to meet your unique needs. Our team has provided comprehensive practical solutions to clients worldwide and is ready to help you too.

With our expertise and commitment to excellence, you can trust us to deliver reliable, durable and efficient winches that will make your operations smoother and more efficient.

Choose Neumann Equipment for your barge winching needs and experience quality, innovation, and customer satisfaction.

Our commitment to quality and expertise in barge winch engineering is unmatched at Neumann Engineering Services. Our team of qualified mechanical engineers uses advanced FEA computer modelling software to design and engineer all our barge winches in-house. We go the extra mile to ensure our products meet all relevant specifications and comply with applicable marine and industry standards by having third-party checks performed when necessary.

When you purchase a custom-made barge winch from us, you can be confident that it has been designed and manufactured to the highest standards. Our internal Quality Assurance Systems fully comply with AS/NZS ISO 9001:2008, ensuring exceptional quality from design to dispatch.

Our barge winches are proudly designed and manufactured at our top-notch Currumbin facility on the stunning Gold Coast of Queensland, Australia. You won’t find a better range of options anywhere else regarding industrial and marine winches.

Contact our knowledgeable Sales, Service and Spare Parts team today to discuss your barge winch requirements and experience the Neumann difference for yourself!

Articles about Barge Winches:

Barge winches are essential equipment used in many industries requiring heavyweight lifting. These winches are specially designed to handle the load of barges, boats, and other heavy equipment. Barge winches are usually mounted on a barge, floating crane, or other vessels, and they help manage the tension of the cable attached to the load. In this essay, we will examine the various types of barge winches, their usage, and the different industries that use them.

Types of Barge Winches

There are different types of barge winches available in the market. The most common types are hydraulic winches and electric winches.

- Hydraulic Winches

Hydraulic winches are the most popular type of barge winches. They are operated using hydraulic fluid, which is pressurized to generate the required power. Hydraulic barge winches are ideal for heavy-duty applications where power is critical. They are commonly used in marine industries, such as dredging, offshore construction, and shipbuilding. - Electric Winches

Electric winches are also commonly used in the barge industry. They are powered by electricity and are ideal for lighter lifting applications. Electric winches are quieter and cleaner to operate than hydraulic winches, making them suitable for indoor applications. They are often used in construction sites, manufacturing facilities, and workshops.

Usage of Barge Winches

Barge winches are used for various applications, including:

- Lifting and handling heavy loads: Barge winches are designed to lift and move heavy loads, such as barges, ships, and other heavy equipment. These winches help to manage the cable’s tension attached to the load, making it easier to move heavy equipment.

- Anchoring and mooring: Barge winches are used to anchor and moor barges and other boats. They help to keep the vessel in place, preventing it from drifting away. Barge winches used for anchoring and mooring are usually equipped with a brake system that prevents the cable from slipping.

- Towing: Barge winches are also used for towing other vessels. They help to pull the vessel along the water, making it easier to navigate through narrow waterways or other obstacles in the water.

Industries that Use Barge Winches

Barge winches are used in many industries that require heavyweight lifting, towing, and anchoring. These include:

- Construction: Barge winches are used in the construction industry to move heavy building materials, such as steel beams, concrete blocks, and prefabricated building components.

- Shipping: Barge winches are used in the shipping industry to load and unload cargo from ships and other vessels. These winches help to move heavy containers from the dock onto the ship and vice versa.

- Offshore: Barge winches are used in the offshore industry for various applications, such as anchoring, mooring, and towing. These winches are designed to withstand harsh marine environments and are used for oil rig operations, platform installation, and other offshore activities.

- Dredging: Barge winches are used in the dredging industry to move sediment from the seabed. These winches help to lift and move the dredge head, making it easier to dredge the sediment from the seabed.

Conclusion

Barge winches are a crucial piece of equipment in many industries that require heavyweight lifting, anchoring, and towing. Different types of barge winches are available, including hydraulic and electric winches, and they are used for various applications. These winches are commonly used in the construction, shipping, offshore, and dredging industries. Choosing the correct type of barge winch for the intended application is essential to ensure safety and efficiency.

Neumann Equipment is an Australian-based company that has become a leader in designing, manufacturing, and supplying high-quality winches to different industries. The company has continued to grow and dominate the industry due to its commitment to quality, innovation, reliability, and exceptional customer service. In this essay, we will discuss Neumann Equipment’s barge winches, concentrating on why they stand out in the market.

Quality design and manufacturing process:

Every product Neumann Equipment designs and manufactures goes through a rigorous process to ensure it meets and exceeds customer expectations. The company uses the latest technology and best-in-class materials to develop its winches, ensuring they are high quality and withstand harsh marine environments. The winches are designed to handle various operations, including barge mooring, towing, and positioning.

Customisation:

At Neumann Equipment, we understand that customers have varying needs and expectations. We offer customisation services to ensure our barge winches meet specific customer requirements. We work with clients to develop solutions that meet their needs, ensuring they have the best equipment for their operations.

Reliability:

Regarding equipment, reliability is a critical factor in determining its effectiveness. Neumann Equipment understands this, and that’s why our winches are built to last. We use high-quality materials and components to ensure our winches are robust and reliable, giving customers peace of mind knowing they are working with dependable equipment.

Exceptional performance:

The effectiveness of any equipment is determined by its performance. Neumann Equipment’s barge winches have been designed to deliver exceptional performance, making them one of the most effective winches in the market. Our winches can handle a range of cargo weights and volumes, making them suitable for a broad range of applications.

Exceptional customer service:

Neumann Equipment prides itself in the design and manufacture of high-quality winches and exceptional customer service. Our team of experts is always ready to assist our clients, ensuring they get the best solutions that meet their needs. We are dedicated to providing customer satisfaction, and our customer-centric approach has earned us a positive reputation in the market.

Conclusion:

In conclusion, Neumann Equipment has established itself as a leader in manufacturing high-quality winches, including barge winches. The company’s commitment to quality, innovation, reliability, customisation, exceptional performance, and exceptional customer service has positioned it as the go-to company for those in need of barge winches. Whether you are in the research or industry sector, Neumann Equipment has the perfect barge winch to meet your requirements.

A Comparative Analysis of Custom-Made Barge Winches: Evaluating Neumann Equipment’s Design Excellence

Barge winches play a crucial role in various marine applications, ranging from lifting and hoisting to positioning and anchoring. The demand for custom-made barge winches has been steadily increasing as businesses seek tailored solutions that align with their specific vessel requirements. In this academic blog, we will conduct a comparative analysis to evaluate the design excellence of Neumann Equipment’s custom-made barge winches, highlighting their key features and advantages over off-the-shelf alternatives.

Design Customisation:

Neumann Equipment’s commitment to delivering custom-made barge winches sets them apart from its competitors. By focusing on individual vessel requirements, their design process ensures that the winches are precisely tailored to meet customers’ unique needs. This level of customisation enhances the winch’s compatibility and functionality within the specific marine environment, enabling seamless integration and improved operational efficiency.

Durability and Reliability:

Marine environments present numerous challenges, including corrosive saltwater, extreme weather conditions, and heavy loads. Neumann Equipment’s barge winches are designed to withstand these demanding conditions, utilising high-quality materials and construction techniques. The integration of robust reduction-style gearboxes and self-aligning outrigger bearings ensures optimal load distribution and longevity, enhancing the winches’ durability and reliability over prolonged usage.

Safety Features:

Safety is paramount in maritime operations, and Neumann Equipment recognises this importance. Their custom-made barge winches are equipped with failsafe brakes, such as spring-applied hydraulic or electric release systems. These brakes provide additional security by preventing unintentional movements or slippage, ensuring the safety of personnel and cargo during lifting, hauling, and anchoring operations.

Versatility and Adaptability:

Neumann Equipment’s barge winches offer remarkable versatility, adapting to a wide range of barge applications. Whether it involves compliant loading doors and ramps, equipment hauling, precise positioning, or secure vessel anchoring, these winches can seamlessly accommodate diverse operational requirements. The flexibility of line pull capacities, hauling line speeds, and optional features like dual-purpose winches and freewheeling gypsies further enhance their adaptability to different scenarios.

Quality Assurance and Compliance:

Neumann Equipment’s unwavering commitment to quality is evident in its design and manufacturing processes. Their in-house mechanical engineering team utilises advanced FEA computer modelling software to ensure precise engineering and adherence to marine industry standards. Additionally, third-party checks are performed when necessary to verify compliance, further solidifying their commitment to delivering products of the highest quality and reliability.

Conclusion:

Neumann Equipment’s custom-made barge winches showcase design excellence that surpasses off-the-shelf alternatives. These winches offer superior performance in demanding marine environments through their meticulous customisation, durability, safety features, adaptability, and commitment to quality assurance and compliance. Businesses can optimise their operations by choosing Neumann Equipment’s barge winches, ensuring efficient and reliable outcomes while meeting their unique vessel requirements.

Ensuring Maritime Safety: An Examination of Neumann Equipment’s High-Quality Barge Winches

Safety is of paramount importance in maritime operations, and the reliability and effectiveness of equipment play a crucial role in ensuring a secure working environment. In this academic blog, we will examine Neumann Equipment’s high-quality barge winches and their contribution to enhancing maritime safety. By exploring their design features, safety mechanisms, and adherence to industry standards; we will highlight how these winches mitigate risks and provide a safe operating environment in various marine applications.

Robust Construction and Material Selection:

Neumann Equipment’s commitment to safety begins with the selection of robust materials and construction techniques. Their barge winches are fabricated from high-quality carbon steel, providing strength and durability to withstand harsh marine conditions. The components undergo meticulous grit blasting, two-pack epoxy primer coating, and heavy-duty marine coatings, ensuring superior corrosion resistance and longevity. This attention to construction details enhances the winches’ reliability and reduces the likelihood of failures that could compromise safety.

Fail-Safe Brake Systems:

Barge winches are frequently involved in lifting, hoisting, and securing heavy loads, making reliable brake systems a critical safety feature. Neumann Equipment’s barge winches are equipped with failsafe brake systems, such as spring-applied hydraulic or electric release mechanisms. These brakes engage automatically in the event of power failure or operator error, preventing uncontrolled movement and ensuring the safety of personnel and cargo. The integration of these fail-safe brake systems adds an extra layer of protection and mitigates potential accidents.

Load Monitoring and Control:

Neumann Equipment’s barge winches often incorporate load monitoring and control mechanisms to ensure safe and controlled operations. These systems provide real-time information about the load being lifted, enabling operators to make informed decisions and prevent overloading situations. Additionally, some winches may feature torque-limiting clutches, providing controlled torque and preventing excessive force on the winch components. Such load monitoring and control features minimise the risk of equipment failure, safeguarding personnel and cargo during critical operations.

Compliance with Safety Standards:

Neumann Equipment prioritises compliance with industry safety standards and regulations. Their internal Quality Assurance Systems align with AS/NZS ISO 9001:2008, ensuring adherence to exceptional quality and safety protocols throughout the design and manufacturing processes. Furthermore, third-party checks are conducted to validate compliance with applicable marine and industry standards. By adhering to these stringent safety guidelines, Neumann Equipment’s barge winches offer users confidence in their performance and safety.

Training and Support:

In addition to providing high-quality barge winches, Neumann Equipment emphasises the importance of proper training and support. They offer comprehensive training programs to equip operators with the necessary knowledge and skills to operate the winches safely and efficiently. Moreover, their knowledgeable sales, service, and spare parts team provides ongoing support, ensuring that customers receive prompt assistance whenever needed.

Conclusion:

Neumann Equipment’s high-quality barge winches prioritise maritime safety through robust construction, failsafe brake systems, load monitoring, compliance with safety standards, and comprehensive training and support. These features collectively enhance operational safety, minimise risks, and ensure a secure working environment in various marine applications. By choosing Neumann Equipment’s barge winches, businesses can demonstrate their commitment to safety and mitigate potential hazards, protecting personnel, cargo, and the overall success of maritime operations.

Engineering Excellence in Barge Winch Design: Unraveling Neumann Equipment’s Methodology

Barge winches are critical in marine operations, requiring meticulous engineering to ensure optimal performance, durability, and safety. In this academic blog, we delve into the engineering excellence of Neumann Equipment’s barge winch design. By examining their methodology, use of advanced technology, and commitment to continuous improvement, we will unravel the factors contributing to their winches’ superior design and highlight their impact on efficiency and reliability in various marine applications.

In-House Mechanical Engineering Expertise:

Neumann Equipment’s engineering excellence stems from its in-house team of qualified mechanical engineers. With their specialised knowledge and experience, these experts drive the design process, applying principles of structural analysis, kinematics, and dynamics. They optimise the winch’s design for maximum performance, efficiency, and longevity by conducting thorough analyses and simulations. This in-house expertise allows for efficient collaboration and quick response to customer requirements, ensuring that the final product meets the highest engineering standards.

Advanced Computer Modeling and Simulation:

Neumann Equipment utilises advanced Finite Element Analysis (FEA) computer modelling software to simulate and analyse the structural behaviour of their barge winches. This technology enables engineers to predict and optimise performance under varying loads, environmental conditions, and operating parameters. By simulating stress distribution, deflection, and material behaviour, Neumann Equipment can refine the winch design for improved reliability, durability, and safety. FEA modelling enhances its ability to deliver optimised solutions that meet each customer’s specific needs.

Material Selection and Construction Techniques:

Engineering excellence extends to the selection of materials and construction techniques employed by Neumann Equipment. By carefully choosing high-quality materials, such as carbon steel, they ensure the winches’ strength, corrosion resistance, and longevity. Incorporating modern fabrication techniques, including precision machining and welding, guarantees precise alignment, robust construction, and efficient performance. Neumann Equipment’s focus on superior materials and construction techniques enhance the winch’s ability to withstand demanding marine environments and provides a foundation for long-term reliability.

Continuous Improvement and Innovation:

Neumann Equipment’s commitment to engineering excellence is evident through its continuous improvement and innovation processes. They actively seek feedback from customers, industry experts, and their team to identify areas for enhancement. This iterative approach allows them to refine design features, incorporate technological advancements, and introduce innovative solutions to meet evolving market demands. By embracing a culture of continuous improvement, Neumann Equipment stays at the forefront of barge winch design, delivering cutting-edge solutions that drive efficiency, reliability, and customer satisfaction.

Compliance with Industry Standards:

Neumann Equipment’s engineering methodology prioritises adherence to industry standards and regulations. They conduct rigorous quality checks throughout the design and manufacturing process to ensure compliance with applicable maritime and industry standards. By meeting these stringent guidelines, Neumann Equipment’s barge winches assure customers that their equipment is safe, reliable, and compliant with the highest engineering and safety standards.

Conclusion:

Neumann Equipment’s engineering excellence in barge winch design is evident through its in-house mechanical engineering expertise, advanced computer modelling and simulation, meticulous material selection and construction techniques, commitment to continuous improvement, and adherence to industry standards. These factors collectively contribute to their winches’ superior performance, durability, and reliability in diverse marine applications. By relying on Neumann Equipment’s engineering expertise, businesses can benefit from cutting-edge design solutions that optimise operations, improve efficiency, and ensure long-term success in the maritime industry.