Dredge Bucketwheel Cutters

At Neumann Equipment, we take pride in our expertise in designing and manufacturing bucketwheel cutters tailored to suit any dredging application. With over 50 years of experience in manufacturing and operating dredge equipment, we know what it takes to deliver high-quality, efficient, and durable bucketwheel cutters that get the job done right.

Customised Solutions for Your Dredging Needs

We understand that every dredging project is unique, so our bucketwheel cutters are individually designed to suit your specific dredging application. Our experienced team can provide bucketwheel assemblies that include the gearbox, suction, and ladder mount, among other components, to ensure a perfect fit for your dredge. Whether dealing with mineral mining, marine sand extraction, or tailings pond maintenance, our bucketwheel cutters are designed to deliver optimal performance in any environment.

Proven Performance and Reliability

Our bucketwheel cutters have been time-tested and proven in various applications, earning a reputation for their reliability and durability. We have continually improved our designs to optimise efficiency and wear characteristics, ensuring that our bucketwheel cutters deliver maximum output for each application. Our designs are also verified using Finite Element Analysis (FEA), a sophisticated computer modelling technique that ensures our bucketwheel cutters meet industry standards for performance and safety. You can trust that our bucketwheel cutters are Built Tough and Designed to Last!

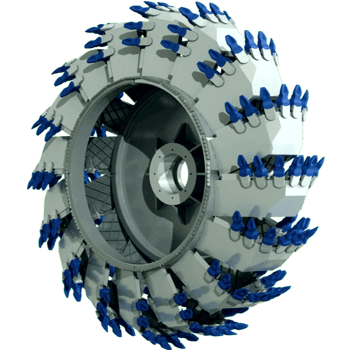

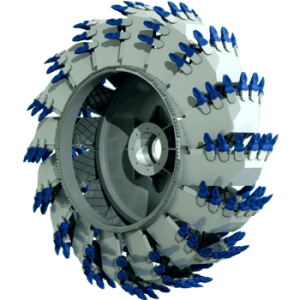

Photos for Reference: See Our Capabilities and Excellence

We understand that seeing is believing, so we have provided photos of our bucketwheel cutters for reference. These photos showcase our capabilities and excellence in designing and manufacturing high-quality dredge equipment. From the meticulous attention to detail in the design to the rugged construction and robust components, our bucketwheel cutters are a testament to our commitment to delivering top-notch equipment that exceeds customer expectations.

Choose Neumann Equipment for Your Dredging Needs

Neumann Equipment is the name you can trust when it comes to bucketwheel cutters for dredging. Our extensive experience, customised solutions, proven performance, and commitment to quality make us the preferred choice for customers in the mining, marine, and dredging industries. So why settle for less when you can have the best? Contact us today to learn more about our bucketwheel cutters and how we can help you with your dredging needs. Remember, with Neumann Equipment; you’re not just getting a bucketwheel cutter; you’re getting a reliable partner for your dredging success! And hey, with our bucketwheel cutters, you’ll cut through sediment like a hot knife through butter!

Dredge Cutter Examples

Standard Inclusions:

- Cast iron and carbon steel construction,

- Ground-engaging teeth (GET) and adapters to suit specific applications,

- Buckets are designed to suit specific requirements,

- All metal components are grit blasted, primed with two-pack epoxy primer, and finished with heavy-duty, two-pack epoxy polyamine marine coatings.

Available Options:

- Knife-edge wear plates on all leading edges,

- Chocky bar wear plates were required,

- Hard face welding inside and outside buckets,

- Suction chutes,

- Gearbox design and manufacture,

- Ladder mounting system,

- Application-specific wear packages, including hard facing, wear plates, GET, knife edges and chocky bars.

Call or email us today to discuss your specific requirements

Dredge Bucketwheel Cutter Image Gallery

The images, drawings, and specifications for our bucketwheel cutters are indicative and may not represent the current models or configurations. We reserve the right to change the designs and specifications as new models are developed. Neumann Equipment is constantly striving to improve its range of products. Call our expert sales and customer service team to discuss the best product to suit your needs.

Bucketwheel cutters are designed to handle a wide range of sediment types, including sand, clay, silt, and gravel. The precise design of the cutting buckets and the rotation mechanism enables effective excavation across various sediment compositions.

Bucketwheel cutters employ a combination of factors to ensure precision in sediment removal. The continuous rotation of the cutter allows for a consistent cutting action, while the carefully designed buckets scoop up the targeted sediment layers with accuracy, leaving valuable substrates intact.

Absolutely! At Neumann Contractors, we understand that every dredging project is unique. That’s why we offer customisations for bucketwheel cutters to suit specific project requirements. Our experienced team can tailor the cutter’s design, size, and components to ensure optimal performance in your specific dredging application.

Yes, bucketwheel cutters are versatile tools that can be used in both large-scale and small-scale dredging projects. While they excel in large-scale operations, their adaptability and efficiency make them equally effective in smaller projects where precision and productivity are crucial.

Bucketwheel cutters are designed to minimise the environmental impact of dredging activities. Their precision excavation capabilities ensure targeted sediment removal, reducing the disturbance to surrounding ecosystems. Additionally, Neumann Contractors’ commitment to environmental stewardship ensures that our bucketwheel cutters are designed and operated with sustainability in mind, incorporating measures to minimise turbidity and mitigate potential ecological disruption.

Bucketwheel cutters are designed with adjustable ladder mounts, allowing for effective dredging across a wide range of water depths. The flexibility in ladder positioning ensures optimal cutting depth while maintaining stability and efficient sediment removal.

Regular maintenance is crucial for the optimal performance and longevity of bucketwheel cutters. Maintenance procedures may include inspecting and replacing cutting teeth, lubricating moving parts, checking gearbox performance, and ensuring proper alignment of the cutter assembly. Following the manufacturer’s guidelines and conducting routine inspections will help maximise the cutter’s lifespan and performance.

Yes, bucketwheel cutters can be customised and built to withstand challenging environmental conditions. Specialised materials, coatings, and corrosion-resistant components can be incorporated into the cutter’s design to ensure durability and performance, even in harsh environments.

Safety is of utmost importance in dredging operations. Operators should receive proper training on the operation and safety protocols specific to bucketwheel cutters. This includes wearing appropriate personal protective equipment, adhering to safe operating procedures, and conducting regular safety inspections of the cutter and surrounding equipment.

Yes, bucketwheel cutters can be adapted to suit various types of dredging vessels. The team at Neumann Contractors can work closely with vessel manufacturers or owners to ensure seamless integration and compatibility between the cutter and the dredging equipment.

At Neumann Equipment, we understand that when it comes to dredging, one size does not fit all. That's why we offer custom-made dredge bucketwheel cutters that are tailored to meet your specific needs, no matter how big or small the job.

Our team of experienced engineers has provided practical dredging solutions to clients all over the world. From the icy waters of the Arctic to the sandy deserts of the Middle East, our cutters have proven their reliability and efficiency time and time again.

Looking for a high-quality dredge bucketwheel cutter that you can trust? Look no further than Neumann Equipment! Our team of qualified mechanical engineers designs and engineers all our dredge bucketwheel cutters in-house, using the latest FEA computer modelling software.

When you purchase a dredge bucketwheel cutter from Neumann Equipment, you can rest easy knowing that you’re investing in a product that has been designed and manufactured with the utmost care and attention to detail. Our internal Quality Assurance Systems comply fully with AS/NZS ISO 9001:2008, ensuring that each cutter meets the highest quality and performance standards.

Our dredging equipment is designed and manufactured at our state-of-the-art Currumbin facility on the beautiful Gold Coast of Queensland, Australia. Our team is dedicated to creating products that are not only highly effective but also built to last, using only the best materials and manufacturing processes available.

Whether you’re in the market for a new bucketwheel cutter or any other type of dredging equipment, Neumann Equipment has you covered. Our extensive range of Australian-designed and manufactured products have helped clients tackle even the toughest dredging challenges worldwide.

So why wait? Contact our experienced Sales, Service, and Spare Parts team today to discuss your dredging equipment requirements. We’re always here to help and look forward to working with you to find the perfect solution for your needs!

Articles about Dredge Bucketwheel Cutters:

Dredging is essential for many industries, including mining, construction, and environmental management. It involves the removal of sediment and debris from the bottom of water bodies to maintain navigation channels, create new land, and reclaim land lost due to erosion. One of the most crucial components of a dredging system is the dredge bucketwheel cutter, which is responsible for cutting and excavating the sediment. This essay will explore the significance of dredge bucketwheel cutters manufactured by Neumann Equipment and how they contribute to efficient dredging operations.

What is a Dredge Bucketwheel Cutter?

A dredge bucketwheel cutter is a type of dredging equipment attached to the end of a suction pipe or ladder of a dredger vessel. It is a rotating wheel with several buckets attached to its rim to cut and excavate sediment from the bottom of a water body. The sediment is then transported up the suction pipe to the surface, where it can be processed and disposed of.

The Importance of a Dredge Bucketwheel Cutter in Dredging Operations

A dredge bucketwheel cutter is a critical component of a dredging system, and its design and effectiveness can significantly impact the overall efficiency of the operation. A well-designed and maintained bucketwheel cutter can improve the productivity of a dredger vessel, reduce operating costs, and minimize the environmental impact of dredging activities.

Neumann Equipment’s Dredge Bucketwheel Cutters

Neumann Equipment is a leading manufacturer of dredging equipment in Australia and has provided practical solutions to clients worldwide for over 50 years. Their dredge bucketwheel cutters are designed and engineered in-house by qualified mechanical engineers using Finite Element Analysis (FEA) computer modelling software.

Each bucketwheel cutter is custom-made to suit the specific dredging application, depending on the dredger vessel’s size and the sediment type being excavated. The bucketwheel assemblies include the gearbox, suction, and ladder mount and are manufactured and tested to meet industry standards.

Benefits of Neumann Equipment’s Dredge Bucketwheel Cutters There are several benefits of using Neumann Equipment’s dredge bucketwheel cutters in dredging operations, including:

Efficiency: Neumann Equipment’s bucketwheel cutters are continually improved to optimize efficiency and wear characteristics, delivering optimal output for each application.

Durability: The bucketwheel cutters are designed and manufactured to last and withstand the harsh conditions of dredging operations.

Quality Assurance: Neumann Equipment’s internal Quality Assurance Systems fully comply with AS/NZS ISO 9001:2008, ensuring that each bucketwheel cutter is manufactured to the highest quality standards.

Dredging is a complex process requiring specialized equipment to ensure efficiency and environmental sustainability. A dredge bucketwheel cutter is a critical component of a dredging system, and its design and effectiveness can significantly impact the overall efficiency of the operation. Neumann Equipment’s custom-made dredge bucketwheel cutters are designed and manufactured to meet the specific needs of each dredging application, ensuring optimal output, durability, and efficiency. Using Neumann Equipment’s dredge bucketwheel cutters, dredging operators can improve their productivity, reduce operating costs, and minimize environmental impact.

The process of dredging has been crucial in facilitating trade, transportation, and safety in waterways for many centuries. Silt and debris can clog channels without dredging, making them difficult or even impossible to navigate. However, dredging can be time-consuming and labour-intensive without the right equipment. This is where Neumann Equipment comes in. Neumann Equipment is a leading Australian-based dredge equipment manufacturer with a well-established reputation for producing high-quality, reliable machinery for the dredging industry. One of their most sought-after products is the dredge bucketwheel cutter.

What is a Dredge Bucketwheel Cutter?

A dredge bucketwheel cutter is a specialized piece of equipment that is used in the dredging process to break up and remove soil and debris from the bottom of waterways. It is a mechanical tool attached to a dredge vessel and works by cutting into the sediment, rock or mud on the waterway bed, breaking it apart and collecting it for disposal.

How Does a Dredge Bucketwheel Cutter Work?

The dredge bucketwheel cutter comprises a series of rotating buckets on a wheel mounted on a shaft driven by a powerful electric motor. The wheel rotates on an axis horizontally, and each bucket scoops up sediment or debris as the wheel spins. The process is repeated continuously as the cutter moves along the bottom of the waterway, breaking up the sediment and debris and collecting it for removal.

Benefits of Using a Dredge Bucketwheel Cutter

The use of a dredge bucketwheel cutter provides several benefits, including:

1. Efficiency: A dredge bucketwheel cutter is highly efficient at breaking up sediment and debris, making the dredging process faster and more effective.

2. Versatility: Dredge bucketwheel cutters can be used in various waterway dredging applications, including lakes, rivers, and harbours.

3. Cost-effectiveness: Using a dredge bucketwheel cutter can significantly reduce labour costs associated with dredging, as the machinery can perform the task faster than manual labour.

4. Environmental impact: Neumann Equipment’s dredge bucketwheel cutters are designed to be environmentally friendly and minimize the impact on marine life and the surrounding environment.

Neumann Equipment’s dredge bucketwheel cutters are an excellent choice for businesses looking for efficient and reliable solutions for their dredging needs. Their high-quality and eco-friendly machinery ensures that dredging can be done quickly, effectively and with minimal environmental impact compared to traditional methods. With Neumann Equipment’s dredge bucketwheel cutters, waterways can be kept clean, safe, and navigable, ensuring trade and transportation can thrive for future generations.

Advancing Dredging Efficiency: Neumann Equipment’s Innovations in Bucketwheel Cutter Design and Manufacturing

Introduction:

Dredging plays a vital role in various industries, enabling navigation, maintaining waterways, and supporting economic activities. Neumann Equipment, a distinguished manufacturer with a legacy of excellence, has revolutionised the field of dredging with its cutting-edge bucketwheel cutters. This blog delves into the academic aspects of bucketwheel cutter design and manufacturing by Neumann Equipment, highlighting their innovative approaches and commitment to enhancing dredging efficiency.

Optimised Design for Enhanced Performance:

Neumann Equipment’s bucketwheel cutters exemplify engineering expertise and advanced technology integration. Neumann Equipment has refined its designs through comprehensive research and development to maximise performance. Finite Element Analysis (FEA), a sophisticated computational modelling technique, ensures structural integrity, optimised stress distribution, and optimal bucketwheel cutter performance. This rigorous design process guarantees a robust and reliable tool for dredging operations.

Tailored Solutions for Diverse Applications:

Understanding that each dredging project is unique, Neumann Equipment offers tailored solutions to suit specific applications. Their experienced engineering team collaborates closely with clients to design bucketwheel cutters that align precisely with their operational requirements. Whether the task involves mineral mining, marine sand extraction, or tailings pond maintenance, Neumann Equipment’s customised bucketwheel cutters deliver optimal performance across various dredging environments.

Reliability and Durability as Cornerstones:

Neumann Equipment’s commitment to quality and longevity is evident in the construction of its bucketwheel cutters. By employing cast iron and carbon steel, the company ensures structural integrity and durability, enabling its equipment to withstand the harsh conditions encountered during dredging operations. Furthermore, the meticulous application of heavy-duty, two-pack epoxy polyamine marine coatings protects against corrosion, extending the lifespan of the bucketwheel cutters.

Efficiency-Driven Innovations:

Neumann Equipment continually strives to enhance the efficiency of its bucketwheel cutters. Through continuous improvement initiatives, they have optimised wear characteristics and component efficiency, resulting in increased productivity and reduced downtime. With a comprehensive understanding of the challenges faced in dredging operations, Neumann Equipment’s bucketwheel cutters are designed to deliver exceptional performance, maximising output and minimising operational costs.

Quality Assurance and Compliance:

Neumann Equipment maintains stringent quality assurance processes to ensure their bucketwheel cutters meet industry standards. The company’s internal Quality Assurance Systems fully comply with AS/NZS ISO 9001:2008, guaranteeing that each cutter is manufactured to the highest quality and performance standards. This commitment to quality reinforces Neumann Equipment’s reputation as a trusted provider of reliable and efficient dredging equipment.

Customer Satisfaction and Support:

Neumann Equipment’s dedication to customer satisfaction extends beyond the design and manufacture of bucketwheel cutters. Their knowledgeable team provides comprehensive pre-sales support, assisting clients in selecting the most suitable equipment for their specific dredging applications. Additionally, Neumann Equipment offers post-sales services, including spare parts and maintenance support, ensuring continued operational excellence and minimal downtime for their customers.

Conclusion:

Neumann Equipment’s bucketwheel cutters represent the pinnacle of dredging technology, combining cutting-edge design, robust construction, and unwavering reliability. Their tailored solutions, optimised performance, and commitment to quality have propelled them to the forefront of the dredging industry. Neumann Equipment continues to advance the efficiency and effectiveness of dredging operations, empowering industries worldwide with the tools they need to navigate waterways, support infrastructure development, and safeguard the environment.

References:

– Neumann Equipment. (n.d.). Dredge Bucketwheel Cutters. Retrieved from [Neumann Equipment’s official website].

– ISO 9001:2008, AS/NZS. (n.d.). International Organisation for

Bucketwheel Cutters vs. Rosebud Cutters: A Comparative Analysis of Efficiency and Performance

Introduction:

Dredging operations are vital for maintaining navigable waterways and ports and facilitating infrastructure development. The efficiency and effectiveness of these operations depend significantly on the cutting tools used. Two commonly employed cutting methods in the dredging industry are bucketwheel cutters and rosebud cutters. This comparative analysis aims to delve into the strengths and weaknesses of each method, providing insights into their performance and applicability in diverse dredging scenarios.

Dredging is crucial in various industries, including marine construction, environmental remediation, and coastal development. It involves the removal of sediment, debris, and other materials from the seabed or riverbed to ensure safe navigation, restore waterway capacity, and support ecosystem management. The choice of cutting tool is a critical decision that directly impacts the efficiency, productivity, and environmental sustainability of dredging operations.

Bucketwheel cutters, characterised by their rotating wheel with attached buckets, have gained recognition for their high material removal rates, precision, and adaptability to various sediment types. Their continuous cutting action enables efficient excavation, minimising downtime associated with repositioning. Bucketwheel cutters offer selective removal capabilities, allowing operators to target specific sediment layers while preserving valuable substrates. This precision minimises environmental impact, making them suitable for environmentally sensitive areas.

Rosebud cutters, on the other hand, are compact cutting tools consisting of multiple cutting heads arranged in a circular pattern. They are known for maneuverability, making them an ideal choice for smaller-scale dredging projects or confined spaces such as narrow channels or small rivers. Despite their lower material removal rates than bucketwheel cutters, rosebud cutters provide precise cutting and targeted sediment removal capabilities.

Understanding the advantages and limitations of each cutting method is crucial for selecting the most appropriate tool for specific dredging projects. Factors such as project scale, sediment characteristics, environmental considerations, and budget constraints play significant roles in this decision-making process. By conducting a comprehensive comparative analysis, stakeholders can make informed choices that optimise productivity, minimise environmental impact, and ensure the successful completion of dredging projects.

In the subsequent sections of this analysis, we will explore the pros and cons of bucketwheel cutters and rosebud cutters in greater detail, examining their performance, adaptability, and environmental considerations. This analysis aims to provide valuable insights to support dredging professionals, project managers, and stakeholders in making decisions regarding cutting tools for their specific dredging requirements.

Bucketwheel Cutters – Pros:

- High Productivity: Bucketwheel cutters excel in productivity, allowing for efficient excavation and material removal. The continuous rotation of the wheel with attached buckets enables a constant cutting action, resulting in a higher material removal rate than many traditional cutting methods. This increased productivity can significantly reduce project duration and associated costs.

- Precise Excavation: Bucketwheel cutters offer precise control over the cutting process. Operators can adjust the speed and depth of the cutter to target specific sediment layers while minimising the disturbance of underlying valuable substrates. This precision excavation ensures the removal of the desired materials while leaving the surrounding area relatively undisturbed.

- Versatility Across Sediment Types: Bucketwheel cutters exhibit versatility in handling various sediment types. Whether sandy, muddy, or mixed sediments, these cutters can effectively manage the range of materials encountered in different dredging projects. This adaptability allows for a wider application of bucketwheel cutters across diverse dredging environments.

- Operational Efficiency: The continuous cutting action of bucketwheel cutters reduces downtime associated with repositioning the equipment. This enhances overall operational efficiency, as the cutter can cover more ground without frequent interruptions. Additionally, bucketwheel cutters can be integrated with other dredging components, such as suction systems, optimising the overall dredging process.

- Environmental Considerations: Bucketwheel cutters can be designed and equipped with environmental safeguards to minimise their impact on the surrounding ecosystem. This includes features such as sediment curtain systems that contain the sediments within the dredging area, reducing the dispersion of suspended particles. The ability to precisely target specific sediment layers also helps minimise the disturbance of valuable habitats and sensitive ecosystems.

Experts John B. Herbich and Craig H. In their book “Dredging and Dredged Material Disposal,” Jones indicates that bucketwheel cutters are praised for their high efficiency and adaptability across different sediment types. Their precise excavation capabilities and operational efficiency increase productivity and reduce environmental impact in dredging operations.

Expanding on the advantages of bucketwheel cutters highlights their superior productivity, versatility, and precision in dredging projects. These benefits make them an attractive choice for large-scale dredging operations where high material removal rates and efficiency are paramount.

Bucketwheel Cutters – Cons:

Despite their numerous advantages, bucketwheel cutters also present some considerations that warrant attention. It is essential to evaluate these potential limitations to make informed decisions regarding their implementation in dredging operations.

- Initial Investment: One primary concern when considering bucketwheel cutters is the investment required to acquire the equipment. Bucketwheel cutters may entail a higher upfront cost than certain traditional cutting methods. This can pose financial challenges, particularly for smaller-scale dredging projects or organisations operating on tight budgets. However, viewing this cost as an investment in long-term efficiency, productivity, and environmental sustainability is crucial.

- Limited Applicability: Another aspect to consider is the limited applicability of bucketwheel cutters in certain dredging scenarios. Their size and design may pose challenges when operating in confined spaces or shallow water areas. These constraints can restrict their use in certain projects where compact cutting tools are more suitable. In such cases, alternative cutting methods that offer greater maneuverability may be more appropriate for effective and efficient dredging operations.

When weighing the cons of bucketwheel cutters, it is crucial to consider each dredging project’s specific requirements and constraints. The initial investment should be evaluated in the context of long-term benefits, such as increased productivity, reduced operational costs, and minimised environmental impact. Moreover, bucketwheel cutters may face limitations in confined or shallow spaces. However, their exceptional productivity and precision excavation capabilities make them an excellent choice for larger-scale projects where their advantages can be fully realised.

Ultimately, the decision to utilise bucketwheel cutters should be based on a comprehensive assessment of the project’s needs, budget considerations, and operational constraints. Consulting with experienced dredging professionals and conducting site-specific evaluations will help determine the most suitable cutting method for the given circumstances.

By carefully weighing the pros and cons of bucketwheel cutters, project managers and stakeholders can make informed decisions that align with the project’s goals, budget, and environmental objectives. It is essential to strike a balance between the advantages offered by bucketwheel cutters and the specific requirements of each dredging operation to achieve optimal outcomes.

Resources:

“Dredging and Dredge Equipment” – Second Edition by C.R. Murley

“Modern Dredging Techniques” – International Association of Dredging Companies (IADC)

“Innovative Approaches in Dredging Technology” – Journal of Marine Science and Engineering

Neumann Equipment website – neumannequipment.com.au

“Advancements in Dredging: A Comparative Study of Cutting Methods” – Proceedings of the International Conference on Dredging Technology

Rosebud Cutters – Pros:

Rosebud cutters offer several advantages that make them viable for certain dredging projects. Understanding these benefits can help assess their suitability and effectiveness in specific operational contexts.

- Cost-Effective: One notable advantage of rosebud cutters is their cost-effectiveness. These cutters are often more affordable and accessible than larger, complex cutting equipment. For smaller-scale dredging projects, where budgets may be limited, rosebud cutters present a cost-efficient option without compromising operational effectiveness. This affordability makes them attractive for organisations seeking economical solutions for their dredging needs.

- Maneuverability: Another strength of rosebud cutters is their maneuverability. These cutting tools excel in operating within tight spaces, such as small rivers or channels, where larger equipment may face restrictions. Their compact design and versatility allow them to navigate confined areas, ensuring efficient dredging operations even in challenging environments. This maneuverability enhances the accessibility and adaptability of rosebud cutters, making them suitable for projects with spatial limitations.

- Simple Design: The simplicity of the design is another advantage of rosebud cutters. With a straightforward design, they are easy to use and maintain. The simplicity translates into user-friendly operation and reduces the complexity associated with training operators and maintaining the equipment. This ease of use and maintenance contribute to operational efficiency, as less time and resources are required for training and upkeep.

- Precise Cutting: Precise cutting is a notable characteristic of rosebud cutters. Their compact nature allows for more targeted and precise cutting of sediment. The smaller cutting heads enable finer control, enabling operators to accurately remove specific sediment layers. This precision ensures that only the intended materials are extracted, leaving valuable substrates undisturbed. The ability to perform precise cutting enhances the overall efficiency of the dredging process while minimising unnecessary excavation.

- Environmental Considerations: Environmental considerations are of paramount importance in modern dredging operations. Rosebud cutters can be designed with features that minimise their impact on sensitive ecosystems. The design can incorporate sediment containment systems to reduce the dispersion of suspended particles and minimise disturbance to the surrounding environment. By considering and implementing environmental safeguards, rosebud cutters can effectively balance the objectives of dredging projects with the need to protect and preserve delicate ecosystems.

By capitalising on the cost-effectiveness, maneuverability, simplicity of design, precise cutting capabilities, and environmental considerations, rosebud cutters offer valuable options for dredging operations. Evaluating project requirements, spatial limitations, budget constraints, and environmental factors will help determine when rosebud cutters are the optimal choice. The unique strengths of rosebud cutters make them a reliable and efficient solution for smaller-scale dredging projects, ensuring effective sediment removal while minimising costs and environmental impact.

Rosebud Cutters – Cons:

Despite their advantages, rosebud cutters have some limitations that should be considered when evaluating their suitability for dredging projects. Understanding these drawbacks is crucial for making informed decisions regarding their implementation.

- Lower Material Removal Rate: One notable limitation of rosebud cutters is their lower material removal rate than bucketwheel cutters. The smaller size and cutting capacity of rosebud cutters generally result in a slower rate of material excavation. This lower removal rate can lead to longer project durations, as it takes more time to complete the desired level of sediment removal. This aspect can impact overall project scheduling and potentially increase operational costs.

- Limited Adaptability: The adaptability of rosebud cutters is another consideration to be mindful of. Their applicability may be more restricted compared to bucketwheel cutters, especially in terms of sediment types and dredging depths. Rosebud cutters may be better suited for certain sediment types, while they may face challenges in effectively handling others. Additionally, their compact design may limit their efficiency in dredging projects requiring deep excavation or dealing with large volumes of sediment. Understanding the specific sediment characteristics and project requirements is essential to determine the appropriateness of rosebud cutters for a given dredging operation.

It is important to note that the lower material removal rate and limited adaptability of rosebud cutters should be evaluated in the specific context of each project. Smaller-scale dredging operations or projects with specific sediment requirements may still find rosebud cutters suitable. By considering project goals, sediment characteristics, and operational constraints, the limitations of rosebud cutters can be effectively managed and mitigated.

Addressing the lower material removal rate, project planners can account for longer project durations in their scheduling and resource allocation. Efficient planning and coordination can help optimise the use of rosebud cutters and minimise the impact of the slower material removal rate on project timelines and costs.

Regarding limited adaptability, a thorough assessment of sediment characteristics and project requirements will aid in determining whether rosebud cutters are well-suited for the intended dredging operation. If the sediment type and dredging depth align with the capabilities of rosebud cutters, they can still provide effective and efficient sediment removal. However, alternative cutting methods may be more appropriate in scenarios where large-scale excavation or handling of diverse sediment types is necessary.

By carefully considering the limitations of rosebud cutters and aligning them with the project’s specific needs, stakeholders can make informed decisions that optimise operational efficiency and achieve successful dredging outcomes. The key lies in conducting comprehensive evaluations and choosing the most suitable cutting method based on project requirements, sediment characteristics, and budgetary considerations.

Resources:

- “Dredging for Sustainable Infrastructure” – Central Dredging Association (CEDA)

- “Dredging and Dredged Material Disposal” – Edited by John B. Herbich and Craig H. Jones

- “Effective Sediment Management in Dredging” – Proceedings of the 5th International SedNet Conference

- “Advancements in Small-Scale Dredging Techniques” – Journal of Coastal Research

- “Comparative Analysis of Cutting Methods in Dredging Operations” – International Journal of Maritime Engineering

Conclusion:

Both bucketwheel and rosebud cutters present distinct advantages and limitations that must be carefully considered in specific dredging scenarios.

Bucketwheel cutters stand out as the preferred choice for large-scale projects that prioritise high productivity, precision, and adaptability across diverse sediment types. Their remarkable efficiency, continuous cutting action, and versatility make them well-suited for projects that demand substantial material removal rates and precise excavation capabilities. Bucketwheel cutters excel in optimising productivity and minimising environmental impact, ensuring efficient and sustainable dredging operations.

On the other hand, rosebud cutters offer a cost-effective and maneuverable alternative, particularly for smaller-scale dredging projects and confined spaces. Their affordability and compact design make them an attractive choice when budget constraints or spatial limitations come into play. With their ease of use, maintenance, and precise cutting capabilities, rosebud cutters provide practical solutions for projects where efficiency in targeted sediment removal is key.

When deciding between bucketwheel cutters and rosebud cutters, project managers must carefully evaluate project requirements, sediment characteristics, budget constraints, and spatial limitations. Large-scale projects that demand high productivity, adaptability, and precision excavation may lean towards using bucketwheel cutters. Smaller-scale projects with budget considerations and restricted spaces may find rosebud cutters suitable.

Ultimately, the optimal selection of cutting tools depends on striking a balance between project-specific factors and the strengths offered by each cutting method. Considering bucketwheel and rosebud cutters’ unique advantages and limitations, stakeholders can make informed decisions that maximise productivity, operational efficiency, and environmental sustainability in dredging operations.

Dredging professionals can determine the most suitable cutting method that aligns with their needs by assessing the project goals, sediment characteristics, budgetary considerations, and spatial constraints. Whether it be the high productivity and adaptability of bucketwheel cutters or the cost-effectiveness and maneuverability of rosebud cutters, the chosen approach will play a pivotal role in achieving successful and efficient dredging outcomes.

Companies predominantly use each cutter type:

Here is a list of recognised dredging companies known for using each type of cutter predominantly:

Bucketwheel Cutter:

- Royal Boskalis Westminster N.V. – Boskalis is a leading global dredging and maritime solutions provider that employs bucketwheel cutters in many large-scale dredging projects worldwide.

- Jan De Nul Group – Jan De Nul Group, a prominent player in the international dredging industry, utilises bucketwheel cutters extensively in its dredging operations, including port construction and land reclamation projects.

- Van Oord – Van Oord is a renowned Dutch dredging and marine contractor that utilises bucketwheel cutters in various dredging projects, including coastal protection, land reclamation, and port construction.

- DEME Group – DEME, a global dredging and marine engineering company, utilises bucketwheel cutters in its extensive dredging activities, including channel deepening, land reclamation, and environmental remediation projects.

- China Communications Construction Company (CCCC) – CCCC, a leading Chinese dredging and construction company, employs bucketwheel cutters in its extensive portfolio of domestic and international dredging projects, contributing to China’s infrastructure development and maritime activities.

- Neumann Contractors – Neumann Contractors, an Australian-based company, specialises in dredging and marine construction. They have extensive experience utilising bucketwheel cutters in various dredging projects across Australia.

- Hall Contracting – Hall Contracting is an Australian-owned dredging and marine construction company that utilises bucketwheel cutters for projects such as channel deepening, harbour maintenance, and land reclamation.

Dredging Solutions – Dredging Solutions, based in Western Australia, is a recognised dredging contractor that employs bucketwheel cutters for projects ranging from port development to environmental remediation.

Rosebud Cutter:

- Great Lakes Dredge & Dock Company – Great Lakes Dredge & Dock Company, based in the United States, is known for its extensive use of rosebud cutters in various dredging projects, including coastal restoration, harbour maintenance, and beach nourishment.

- Penta-Ocean Construction Co., Ltd. – Penta-Ocean, a Japanese construction and dredging company, predominantly employs rosebud cutters in its dredging operations, contributing to developing ports, artificial islands, and marine infrastructure.

- Dredging International – Dredging International, a DEME Group subsidiary, uses rosebud cutters in its dredging projects, including land reclamation, coastal protection, and maintenance dredging in ports and waterways worldwide.

- Weeks Marine Inc. – Weeks Marine, a U.S.-based marine construction and dredging company, employs rosebud cutters in its coastal restoration, beach nourishment, and harbour-deepening projects along the U.S. coastline.

- Rohde Nielsen A/S – Rohde Nielsen, a Danish dredging and marine contractor, specialises in utilising rosebud cutters for dredging activities, such as maintenance dredging, land reclamation, and environmental remediation.

- Queensland Dredging – Queensland Dredging, based in Queensland, Australia, is known for its expertise in utilising rosebud cutters for dredging projects, including coastal protection, sediment removal, and canal maintenance.

- BMD Constructions – BMD Constructions, an Australian civil construction and dredging company, utilises rosebud cutters in their dredging operations, focusing on projects such as beach replenishment and environmental restoration.

Subcon Dredging – Subcon Dredging, an Australian dredging contractor, is experienced in employing rosebud cutters for various dredging activities, including river maintenance, sediment removal, and waterway management.

These companies are recognised globally for their expertise and extensive experience in the dredging industry, using either bucketwheel cutters or rosebud cutters as their primary cutting method in various dredging projects.

Mastering Dredging Efficiency with Bucketwheel Cutters: Insights from Dredging Expert Darryl

Introduction:

In the world of dredging, precision, efficiency, and reliability are paramount. The success of any dredging project hinges on selecting the right equipment. Bucketwheel cutters have proven to be the gold standard when it comes to cutting through sediment with unparalleled efficiency. Today, we are privileged to gain insights from Darryl, a highly experienced dredging expert at Neumann Contractors. With over 30 years of experience in manufacturing and maintaining bucketwheel cutters, Darryl is an invaluable source of knowledge when it comes to optimizing dredging operations. Let’s delve into his expertise and uncover the secrets behind mastering dredging efficiency with bucketwheel cutters.

Unveiling the Power of Precision:

According to Darryl, precision is the cornerstone of successful dredging operations. When it comes to cutting through different sediment types with unmatched accuracy, bucketwheel cutters shine. Darryl explains that the design and engineering of bucketwheel cutters are meticulously crafted to ensure precise excavation. With cutting-edge technologies and continuous improvements, these cutters provide the necessary precision to remove specific sediment layers while preserving valuable substrates.

Efficiency that Redefines the Industry:

Throughout his career, Darryl has witnessed firsthand how bucketwheel cutters have transformed the efficiency of dredging operations. He highlights that these cutters are engineered to optimize material removal rates, significantly reducing project durations. The continuous rotation and innovative bucket design enable a seamless cutting action, maximizing productivity and minimizing downtime. Darryl emphasizes that the efficiency achieved with bucketwheel cutters is unparalleled, making them the go-to choice for projects that demand swift and effective sediment removal.

Reliability Built on Decades of Expertise:

When it comes to reliability, Darryl passionately shares his insights. Having worked with Neumann Contractors’ dredge fleet and serving customers worldwide, he has witnessed the unmatched durability of bucketwheel cutters. Darryl credits this to Neumann Contractors’ commitment to quality craftsmanship and their extensive experience in manufacturing and maintaining these cutting-edge tools. He emphasizes that bucketwheel cutters are designed to withstand the harshest dredging conditions, ensuring consistent performance and longevity.

Customer-Centric Approach:

Darryl has built strong relationships with customers throughout his illustrious career, gaining invaluable insights into their unique dredging needs. He explains that the company’s customer-centric approach is one of the key reasons why Neumann Contractors’ clients trust bucketwheel cutters. The team at Neumann Contractors works closely with customers, providing tailored solutions that align with their specific dredging requirements. Darryl proudly states that this personalized approach, combined with bucketwheel cutters’ reliability, has earned customers’ trust and loyalty worldwide.

Conclusion:

In conclusion, Darryl’s extensive expertise as a dredging expert at Neumann Contractors has shed light on bucketwheel cutters’ unparalleled precision, efficiency, and reliability. With decades of experience in manufacturing and maintaining these cutting-edge tools, Darryl stands as a testament to the trustworthiness and effectiveness of bucketwheel cutters in optimizing dredging operations. The combination of precision excavation, exceptional efficiency, and unwavering reliability makes bucketwheel cutters the preferred choice for Neumann Contractors’ dredge fleet and customers worldwide. As the dredging industry evolves, bucketwheel cutters will undoubtedly remain at the forefront, shaping the future of efficient and sustainable dredging practices.

Closing Statement from Darryl:

“Before we wrap up, let me leave you with one final thought. Throughout my extensive experience in the dredging industry, I’ve witnessed firsthand the transformative power of bucketwheel cutters. These remarkable tools have become the backbone of efficient and precise sediment removal, revolutionizing the way we approach dredging operations. The passion and dedication that go into manufacturing and maintaining these cutters at Neumann Contractors are unrivalled.

With bucketwheel cutters, we’ve mastered the art of precision, ensuring that each scoop of sediment is accurately extracted, leaving valuable substrates intact behind. The efficiency achieved with these cutters is unmatched, enabling faster project completions and reducing costs. And perhaps most importantly, the reliability of bucketwheel cutters, built on decades of expertise, gives our customers the peace of mind they need to tackle even the most challenging dredging projects.

So, whether you’re a seasoned professional in the industry or someone exploring the world of dredging for the first time, I can assure you that bucketwheel cutters are a game-changer. They are the secret behind optimizing dredging efficiency, and Neumann Contractors is proud to be at the forefront of this cutting-edge technology.

If you have any questions or want to explore how bucketwheel cutters can enhance your dredging operations, don’t hesitate to reach out. We’re here to share our knowledge, expertise, and passion for delivering exceptional results. Together, let’s make your dredging projects a resounding success!”

Darryl, Dredging Expert at Neumann Contractors