Hoisting Winches

Reliable and Efficient Hoisting Winches for Industrial, Mining, and Marine Applications

When it comes to finding a reliable and efficient hoisting winch for your industrial, mining, or marine applications, Neumann Equipment is the go-to solution. We understand the importance of having a dependable and high-performing hoisting winch that can handle the demanding tasks of your industry. That’s why our hoisting winches are designed and built to exceed industry standards, providing you with the peace of mind you need regarding safety and performance. Neumann Equipment has a proven track record of delivering reliable hoisting winches that withstand the most challenging conditions. Our winches are meticulously engineered and manufactured using the latest technologies and the highest quality materials. We prioritise durability, efficiency, and longevity, ensuring our winches can handle heavy loads and continuous use without compromising performance.

Diverse Applications of Neumann Equipment’s Custom Hoisting Winches

At Neumann Equipment, we offer custom hoisting winches catering to a wide range of applications. Our versatile winches can be tailored to meet specific requirements, making them suitable for various industries and tasks. Whether you need a hoisting winch for conveyor tensioning/take-up, conveyor chute positioning, borehole pump and sampling, coal harrow, materials lifting, marine recovery, drill rig, or crane operations, Neumann Equipment has you covered. Our extensive experience in designing and manufacturing hoisting winches allows us to provide solutions for diverse applications, ensuring that our winches are a perfect fit for your specific needs.

Engineering Excellence and Compliance with Industry Standards

Neumann Equipment sets itself apart through its commitment to engineering excellence and adherence to industry standards. We employ advanced techniques, such as Finite Element Analysis (FEA), to verify the design of our hoisting winches. This ensures optimal performance, structural integrity, and safety in all our products. Our hoisting winches undergo third-party verification by a Registered Professional Engineer Queensland (RPEQ) to further demonstrate our dedication to quality. This independent evaluation guarantees that our winches meet all relevant specifications and comply with applicable marine and industry standards. We adhere to respected standards like AS 1418 Cranes, Hoists and Winches, DNV-OS-H2O5 Offshore Lifting, and Lloyd’s Register, ensuring our winches meet or exceed industry regulations.

Trust Neumann Equipment for Dependable Hoisting Winches

When choosing a hoisting winch that you can count on, Neumann Equipment is the trusted name in the industry. With our commitment to quality, engineering expertise, and compliance with industry standards, we provide hoisting winches that are reliable, durable, and built to last. Neumann Equipment’s hoisting winches are designed and manufactured in-house by qualified mechanical engineers using cutting-edge technologies. Our internal Quality Assurance Systems, compliant with AS/NZS ISO 9001:2008, guarantee that every aspect of the design and manufacturing process meets the highest standards of quality and reliability.

When you choose Neumann Equipment for your hoisting winch needs, you can expect exceptional products and outstanding customer service. Our experienced Sales, Service, and Spare Parts team is dedicated to helping you find the perfect hoisting winch solution for your business—Trust Neumann Equipment to deliver hoisting winches that meet your requirements and elevate your operations.

Standard Inclusions:

- Fail-safe multi-disc spring-applied brake,

- The drum is supported with a fully sealed self-aligning outrigger bearing,

- Carbon steel construction,

- Rope terminator designed per AS2074-Wedge Type Sockets,

- Reduction gearbox,

- Factory acceptance testing in accordance with AS1418.2,

- All components are grit blasted and primed with two-pack epoxy primer and finished with heavy-duty two-pack epoxy polyamine industrial/marine coatings.

Available Options:

- Line lift capacities – up to 100,000kg,

- Hauling line speeds – up to 50 metres per minute,

- Steel or stainless steel construction,

- Overload detection,

- Overspeed detection,

- Slack rope detection,

- Drum overwind detection,

- Electric/hydraulic drive,

- Electric/hydraulic control system,

- Grooved/plain drum,

- Wire feeder/level winder,

- Tension and distance monitoring,

- Custom-designed electric/hydraulic power pack.

Hoist Winches

Call or email us today to discuss your specific requirements

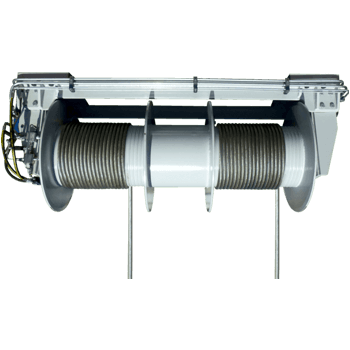

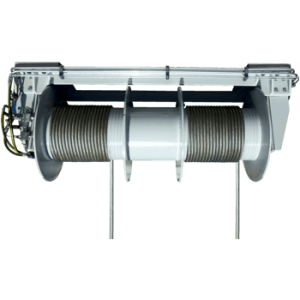

Hoisting Winches Image Gallery

At Neumann Equipment, we understand that a picture is worth a thousand words but also believe in constant innovation and improvement. This means that our hoisting winches may not always look the same as our website’s images, drawings, or specifications.

Rest assured, our commitment to providing the best quality winches in the market remains steadfast. We reserve the right to change the designs and specifications of our products as new models are developed because we’re always striving to improve our range of products to meet the needs of our customers.

We have a team of expert sales and customer service professionals ready to assist you in selecting the perfect hoisting winch for your needs. Call us, and we’ll help you navigate our range of products, answering any questions you have along the way. Choose Neumann Equipment, where innovation and quality are at the forefront of everything we do.

A hoisting winch is a mechanical device for lifting and moving heavy loads in various industries. It consists of a drum or spool around which a cable or rope is wound, allowing for controlled lifting and lowering of loads.

Hoisting winches are used in a wide range of industries, including construction, mining, marine, manufacturing, transportation, and offshore operations. They are employed wherever heavy loads need to be lifted or moved.

When choosing a hoisting winch, important factors to consider include load capacity, line speed, safety features, durability, customization options, compliance with industry standards, and the reputation of the manufacturer.

Yes, hoisting winches can be customised to meet specific requirements. Customisation options include line lift capacities, line speeds, control systems, drum configurations, safety features, and additional accessories.

Hoisting winches can improve safety through the incorporation of features such as emergency stop mechanisms, load monitoring systems, overload protection, limit switches, slack rope detection, and overwind protection. These features help prevent accidents, ensure safe lifting operations, and protect personnel and equipment.

Regular maintenance is essential to keep hoisting winches in optimal condition. Maintenance tasks may include inspecting cables and ropes for wear and damage, lubricating moving parts, checking safety features, and following manufacturer-recommended maintenance schedules.

Yes, hoisting winches can be designed for hazardous environments. They can be equipped with features such as explosion-proof motors, corrosion-resistant coatings, and intrinsically safe controls to ensure safe operation in hazardous conditions.

When selecting a hoisting winch, certifications to consider include ISO 9001:2008 for quality management systems, AS 1418 for cranes, hoists, and winches, DNV-OS-H205 for offshore lifting, and certifications from recognised regulatory bodies such as Lloyd’s Register.

Yes, many hoisting winches can be operated remotely through the use of remote control systems. This allows operators to control the winch from a safe distance, enhancing safety and convenience in various applications.

To ensure you choose the right hoisting winch, it is recommended to consult with reputable manufacturers or suppliers who have experience in your industry. They can assess your specific requirements, provide expert guidance, and recommend the most suitable hoisting winch solution for your needs.

At Neumann Equipment, we don't just make winches- we engineer solutions that work for you. With our years of experience, we have perfected the art of designing and manufacturing high-quality hoist winches tailored to your specific requirements.

Our dedication to quality and innovation has earned us a reputation as a trusted partner for businesses worldwide. Our extensive range of practical solutions has helped clients in various industries succeed, from marine applications to mining and beyond.

So whether you need a winch for heavy-duty lifting or a specialized application, you can count on Neumann Equipment to provide the best quality, reliability, and efficiency. Contact us today to learn how we can help you engineer the perfect solution for your needs.

At Neumann Equipment, we take pride in our hoist winches designed and engineered in-house by qualified mechanical engineers using our cutting-edge FEA computer modelling software. Third parties also check every product to ensure it meets all relevant specifications and complies with applicable marine and industry standards.

Our commitment to quality doesn’t stop there. From design through to dispatch, our internal Quality Assurance Systems are fully compliant with AS/NZS ISO 9001:2008, so you can rest assured that you are in good hands when you choose us for your hoist winch needs.

All our equipment, including the hoist winches, is designed and manufactured in our facility in Currumbin, on the Gold Coast, Queensland. With our state-of-the-art equipment and manufacturing processes, we deliver world-class products that meet the highest standards of quality and reliability.

When you need a hoist winch, you can’t go wrong with our range of options for Australian-designed and manufactured lifting equipment. Whether you need a standard hoist winch or a customized solution, our experienced Sales, Service and Spare Parts team is here to help you find the perfect fit for your business.

Choose Neumann Equipment for your hoist winch needs, and experience the peace of mind of working with a trusted industry leader. Contact us today to learn how we can help you elevate your business with our exceptional hoist winches.

Articles about Hoisting Winches:

Hoisting winches are essential for many industries that require lifting and pulling applications. These winches are designed to be safe and reliable, and several standards and regulations regulate their manufacture. In Australia, several companies, including Neumann Equipment, design and manufacture hoisting winches. This essay provides an overview of the design and manufacture of hoisting winches in Australia, including the specific industry regulations such as AS 1418 Cranes, Hoists, and Winches, DNV-OS-H2O5 Offshore Lifting, and Lloyd’s Register.

Design of Hoisting Winches:

Several industry regulations and standards guide the design of hoisting winches in Australia. These regulations ensure that the winches are safe, reliable, and efficient in their operations. Among these regulations is AS 1418 Cranes, Hoists, and Winches. This standard provides guidelines for designing and manufacturing cranes, hoists, and winches in Australia. It outlines the criteria for these devices’ capacity, safety, and performance, including load capacity, hoisting speed, braking systems, and control mechanisms.

Another vital regulation that guides the design of hoisting winches in Australia is DNV-OS-H2O5 Offshore Lifting. This regulation provides guidelines for the offshore industry’s design, manufacture, and operation of lifting equipment. It outlines the specific requirements for the components of hoisting winches, including the drum, wire rope, braking system, and control mechanisms. Additionally, it provides guidelines for installing, inspecting, and maintaining hoisting winches used in the offshore industry.

Manufacturing of Hoisting Winches:

The manufacturing of hoisting winches in Australia is conducted by several companies specialising in producing lifting equipment. These companies use the guidelines provided by industry regulations and standards, such as AS 1418 and DNV-OS-H2O5, to ensure that the winches are safe and reliable. One such company is Neumann Equipment, a leading manufacturer of hoisting winches in Australia. Neumann Equipment has operated for over 50 years and has a reputation for producing high-quality lifting equipment.

The manufacturing of hoisting winches involves several steps, including the fabrication of components, assembly, and testing. The members of hoisting winches are fabricated using high-quality materials, such as steel, aluminium, and titanium. These materials are selected based on the application’s requirements, including load capacity, hoisting speed, and operating conditions.

Once the components are fabricated, they are assembled into a hoisting winch. The assembly process involves fitting the components together and integrating the control mechanisms, braking systems, and other safety features. The winch is then tested to ensure that it meets the specific requirements of the application and the guidelines provided by industry regulations and standards.

Conclusion:

Hoisting winches are essential components of many industries that require lifting and pulling applications. In Australia, several companies, including Neumann Equipment, designed and manufactured these winches. The design and manufacture of hoisting winches are guided by several industry regulations and standards, including AS 1418 Cranes, Hoists, Winches, DNV-OS-H2O5 Offshore Lifting, and Lloyd’s Register. These regulations ensure that the winches are safe, reliable, and efficient in their operations. The manufacturing process involves several steps, including the fabrication of components, assembly, and testing. By adhering to these requirements, hoisting winches can be used in a variety of industries to safely and effectively handle heavy lifting operations.

Winches are used to lift or pull heavy loads in various industrial and commercial applications. However, not all winches are created equal, and there are distinct differences between lifting winches and hoisting winches. This essay will explore the technical differences and practical uses of these two types of winches.

What is a Hoisting Winch?

A hoisting winch is a mechanical device that is used solely for vertical lifting applications. These types of winches are commonly used in construction sites, mining operations and industrial facilities. Hoisting winches are mainly responsible for moving loads in a vertical direction. They are designed to handle heavy loads safely and efficiently. Some of the main characteristics of hoisting winches include:

- Maximum Safety Features: Hoisting winches are built with multiple safety features, such as automatic brakes and overload protection systems. These features are critical for ensuring safe lifting operations and minimizing the risks of accidents.

- Single-Line Lifting Capacity: Hoisting winches typically have a single-line lifting capacity, which means they can only lift loads in a vertical direction. They are not designed for horizontal pulling applications.

- High Lifting Speeds: Hoisting winches are designed to lift loads at high speeds, which is essential for vertical lifting applications. Depending on the application, these winches can be powered by electric, hydraulic or pneumatic systems.

What is a Lifting Winch?

On the other hand, a lifting winch is a mechanical device designed for both vertical and horizontal lifting applications. Lifting winches are commonly used in marine applications, heavy-duty off-road vehicles, and various industrial applications. Some of the main characteristics of lifting winches include the following:

- Horizontal and Vertical Lifting Capabilities: Lifting winches can lift loads in horizontal and vertical directions, making them more versatile than hoisting winches. They can be used to pull loads or lift them in a vertical direction.

- High Pulling Capacity: Lifting winches are designed to handle high pulling capacities, which makes them ideal for moving heavy loads over long distances. They are commonly used in off-road vehicles for winching a vehicle out of mud or sand.

- Lower Lifting Speeds: Lifting winches tend to have lower lifting speeds than hoisting winches. This is because they are designed to pull loads over long distances, and high lifting speeds are not always necessary.

How to Choose Between Lifting Winches and Hoisting Winches

Choosing between a lifting winch and a hoisting winch mainly depends on the application requirements. If you only need to lift loads in a vertical direction, then a hoisting winch is the best choice. Hoisting winches are built for maximum safety and are ideal for construction sites and mining operations.

However, if you need a winch that can lift and pull loads in both horizontal and vertical directions, a lifting winch is the best option. Lifting winches tend to be more versatile and ideal for marine applications, off-road vehicles, and various industrial applications.

Conclusion:

In conclusion, lifting and hoisting winches have different uses and capabilities that make them suitable for specific applications. It is essential to understand these differences when choosing a winch for a particular application. Ultimately, the right winch choice depends on the nature of the work being performed, the environment, and the load capacity requirements.

Winches pull heavy objects or lift weights in various industries, such as construction, mining, forestry, marine, and electric power. They are designed to provide a mechanical advantage by using a motor, a gearbox, and a cable or rope to exert force on a load. The lifting capacity of a winch is the maximum weight it can safely lift or pull, and it depends on several factors, such as the type of winch, the diameter and length of the cable, the speed of the motor, and the power source. In this essay, we will discuss how to determine the lifting capacity of a winch and what factors you should consider before choosing the right winch for your needs.

Types of Winches:

Several types of winches are available in the market, each with its own lifting capacity and application. Some of the commonly used winches are:

Electric Winches – An electric motor powers these winches and are usually mounted on a vehicle or a boat. Depending on the model and brand, they can lift loads ranging from 200kg to 10,000kg.

Hydraulic Winches – These winches are powered by a hydraulic system and are used in heavy-duty mining and construction applications. They can lift loads ranging from 1,000kg to 100,000 kg, depending on the capacity of the hydraulic system.

Pneumatic Winches – These winches are powered by compressed air and are ideal for applications where electricity or hydraulic power is not available. Depending on the air pressure and flow rate, they can lift loads ranging from 500kg to 5,000kg.

Hand Winches – These winches are manually operated and are used in small-scale applications, such as pulling a boat onto a trailer or hoisting a flag. They can lift loads ranging from 100kg to 1,000kg, depending on the size and strength of the operator.

Capacity Ratings:

The lifting capacity of a winch is usually expressed in pounds (lbs) or kilograms (kg), and it refers to the maximum weight that the winch can lift or pull without risking damage or failure. It is important to note that the lifting capacity of a winch is not the same as its pulling capacity, which is usually higher due to the mechanical advantage provided by the cable or rope. Therefore, it is important to consider the application and the load requirements before choosing a winch based on its pulling capacity.

Factors Affecting Lifting Capacity:

The lifting capacity of a winch depends on several factors, including:

Cable Diameter and Length – The diameter and length of the cable or rope determine the strength and weight capacity of the winch. A thicker and longer cable can lift heavier loads but requires more power to operate.

Motor Power – The motor’s power is measured in horsepower (hp) or watts (W), and it determines how fast and efficiently the winch can lift a load. A higher-powered motor can lift heavier loads but may consume more energy and require a more significant power source.

Gear Ratio – The gear ratio of a winch determines the amount of mechanical advantage it provides, which in turn affects the lifting capacity of the winch. A higher gear ratio provides more lifting capacity but may reduce the speed of the winch.

Line Speed – The line speed of a winch refers to how fast the cable or rope is pulled in, and it affects the lifting capacity of the winch. A slower line speed provides more lifting capacity but may take longer to lift a load.

Ambient Conditions – The lifting capacity of a winch can be affected by the temperature, humidity, altitude, and other external factors that affect the performance of the winch. Therefore, it is essential to consider the ambient conditions and choose a winch that can operate safely and efficiently under those conditions.

Conclusion:

Determining the lifting capacity of a winch is an essential step in choosing the right winch for your needs. It requires careful consideration of several factors, such as the type of winch, the capacity ratings, and the factors that affect lifting capacity. Choosing a winch with the correct lifting capacity ensures safety, efficiency, and reliability in your lifting and pulling operations.

Elevate Your Operations with Hoisting Winches Designed for Safety and Peace of Mind

Hoisting winches play a crucial role in various industries, enabling the lifting and movement of heavy loads with precision and efficiency. However, with the importance of safety in mind, it is essential to consider the top safety features when selecting a hoisting winch. By investing in winches equipped with advanced safety features, businesses can enhance workplace safety, minimise risks, and ensure the well-being of their workforce. This academic blog will explore the top safety features that should be prioritised when choosing hoisting winches.

- Emergency Stop Mechanism:

An emergency stop mechanism is one of the fundamental safety features of hoisting winches. This mechanism allows operators to halt winch operations immediately in emergencies, preventing accidents and potential injuries. It should be easily accessible and intuitively designed for quick and effective responses during critical situations. - Load Monitoring Systems:

To maintain safe lifting operations, hoisting winches should incorporate load monitoring systems. These systems provide real-time information about the lifted load, ensuring it remains within the winch’s rated capacity. With accurate load monitoring, operators can prevent overloading, minimise the risk of structural failures, and maintain safe working conditions. - Overload Detection and Protection:

Hoisting winches should be equipped with overload detection and protection mechanisms to safeguard against overloading situations. These features monitor the load being lifted and automatically halt or limit operations if the load exceeds the winch’s safe working capacity. By preventing overloading, these mechanisms protect personnel and equipment from accidents and damage. - Limit Switches:

Incorporating limit switches in hoisting winches is vital for preventing unsafe movements and potential collisions. These switches set predetermined upper and lower limits for the lifting or lowering motion of the winch. Once these limits are reached, the winch automatically stops or changes direction, ensuring safe and controlled operations. - Slack Rope Detection:

A slack rope detection system is an essential safety feature in hoisting winches, especially when lifting irregularly shaped or fragile loads. This system detects any slack or loose rope and immediately stops the winch to prevent potential entanglement, damage to the load, or accidents caused by an uncontrolled descent. - Overwind Protection:

To ensure safe operations, hoisting winches should incorporate overwind protection mechanisms. These mechanisms prevent excessive rope winding onto the drum, which can cause damage to the winch and compromise lifting safety. Overwind protection features can include automatic shutdown or warning alarms to alert operators and prevent potential hazards.

Conclusion:

Safety should always be a top priority when it comes to hoisting winches. By selecting winches with advanced safety features like emergency stop mechanisms, load monitoring systems, overload detection and protection, limit switches, slack rope detection, and overwind protection, businesses can significantly enhance workplace safety and reduce the risk of accidents. Investing in hoisting winches equipped with these top safety features protects personnel and equipment and contributes to a more efficient and reliable workflow. Choose winches that prioritise safety to elevate your operations with peace of mind and confidence in your lifting processes.

Elevate Your Operations with the Perfect Hoisting Winch Tailored to Your Industry’s Needs

Choosing the right hoisting winch is of utmost importance in industries that rely on heavy lifting and precise load movement. A hoisting winch designed and engineered to meet the unique requirements of your industry can enhance operational efficiency, improve safety standards, and maximise productivity. This academic blog will highlight the significance of selecting the right hoisting winch for your industry and how it can make a substantial difference in your operations.

- Customised Performance:

Each industry has specific demands and challenges when lifting and moving heavy loads. You can ensure optimal performance by choosing a hoisting winch tailored to your industry’s requirements. Customisation options include line lift capacities, line speeds, control systems, drum configurations, and additional features that can be fine-tuned to match your industry’s needs. This level of customisation ensures that the hoisting winch seamlessly integrates into your workflow and provides efficient lifting solutions. - Safety and Compliance:

Different industries have unique safety regulations and compliance standards. When selecting a hoisting winch, it is crucial to consider safety features that align with your industry’s specific requirements. Whether emergency stop mechanisms, overload protection, or load monitoring systems, choosing a winch designed to meet or exceed industry safety standards enhances workplace safety. It reduces the risk of accidents or injuries. Additionally, opting for a winch from a reputable manufacturer with a track record of compliance ensures adherence to industry regulations. - Durability and Reliability:

Industries with demanding lifting applications require hoisting winches built to withstand harsh environments and continuous heavy-duty use. Choosing a winch constructed with high-quality materials and robust components ensures durability and longevity. A winch designed to last in your industry’s unique conditions minimises downtime, reduces maintenance costs, and improves overall operational efficiency. - Versatility and Adaptability:

Industries evolve, and their lifting requirements may change. Opting for a hoisting winch that offers versatility and adaptability allows you to meet changing demands. Look for winches that can be easily modified or equipped with additional features to accommodate new lifting scenarios or handle different loads. This flexibility ensures that your hoisting winch remains relevant and efficient as your industry progresses. - Expert Guidance and Support:

Choosing the right hoisting winch involves understanding your industry’s needs and finding the perfect match. Reputable manufacturers provide expert guidance and support to help you navigate the selection process. Their experienced sales and engineering teams can assess your requirements, recommend suitable options, and assist with customisation to ensure the ideal hoisting winch for your industry.

Conclusion:

Selecting the right hoisting winch for your industry is a decision that can significantly impact operational efficiency, safety, and productivity. By opting for a customised winch to meet industry-specific needs, you can achieve optimised performance, comply with safety regulations, and ensure long-term durability. Choosing a hoisting winch from a reputable manufacturer that offers versatility and provides expert guidance ensures that your operations are elevated to new heights of success. Invest wisely in the perfect hoisting winch tailored to your industry’s requirements and experience the transformative benefits it brings to your lifting processes.