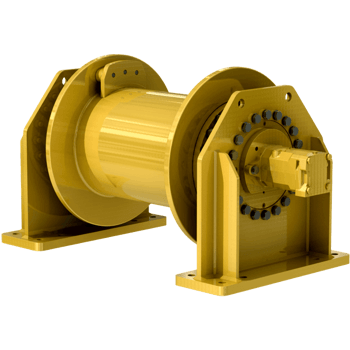

Hauling Winches

Neumann Equipment: Leading Manufacturer of Hauling Winches

Neumann Equipment is a renowned Australian manufacturer of hauling winches specially designed to endure harsh environmental conditions. Our hauling winches are built to last, providing dependable service for years. Our winches are equipped with high-quality components and advanced technology and excel in commercial, industrial, and marine applications. Whether you require winches for conveyor belt replacement, cable hauling, low loader recovery, or dredge retrieval, our hauling winches are up to the task.

Quality Assurance with Finite Element Analysis (FEA)

Neumann Equipment’s hauling winch designs, including Finite Element Analysis (FEA), undergo rigorous testing and verification. This ensures that our winches meet the relevant marine and industry standards, delivering top-notch quality and consistent performance. We take pride in our winches, which are meticulously designed to withstand extreme conditions and surpass expectations.

Tailored Hauling Winches for Specific Requirements

We understand the importance of meeting our client’s unique needs and specifications at Neumann Equipment. Our custom-designed hauling winches testify to our capabilities and commitment to excellence. With our expertise in design and manufacturing, we can provide hauling winches customized to suit your specific applications. From concept to creation, we strive to deliver winches that perfectly match your requirements.

High-Quality Components and Advanced Technology

We recognize the significance of reliable hauling winches in critical operations. That’s why we use only top-grade components and incorporate advanced technology throughout manufacturing. From the initial design phase to the final testing, we ensure that our hauling winches meet the highest quality and performance standards. With Neumann Equipment, you can have confidence in our winches’ durability, efficiency, and longevity.

Trust in Neumann Equipment for Your Hauling Winch Needs

With years of experience and a reputation for excellence and reliability, Neumann Equipment offers the best hauling winches in the market. Our winches are built to last, cost-effective, and easy to maintain. If you’re searching for a hauling winch that you can rely on, contact Neumann Equipment today. Our team is ready to discuss your requirements and provide a custom-designed hauling winch that suits your needs.

Standard Inclusions:

- Spring-applied hydraulic/electric release fail-safe brakes brake,

- Haul winch drums are supported with fully sealed self-aligning bearings,

- The haul winch bases and drums are fabricated from various grades of carbon steel,

- All components are grit blasted and primed with two-pack epoxy primer and finished with heavy-duty two-pack epoxy polyamine coatings.

Available Options:

- Line pull capacities – up to 200 tonnes,

- Hauling line speeds – up to 50 metres per minute,

- Drive motor types – electric or hydraulic,

- Reduction style gearboxes to suit requirements,

- Diesel/electric hydraulic power pack,

- Electrical/hydraulic control systems to suit specific applications,

- Wire feeders to suit the application,

- Distance and tension monitoring,

- Guarding to suit specific requirements,

- Grooved or un-grooved drum shell,

- High-power multiple drive systems.

Hauling Winches Examples

Call or email us today to discuss your specific requirements

Winch Image Gallery

The images, drawings, and specifications for our hauling are indicative and may not represent the current models or configurations. We reserve the right to change the designs and specifications as new models are developed. Neumann Equipment is constantly striving to improve its range of products. Call our expert sales and customer service team to discuss the best product to suit your needs.

A hauling winch is a mechanical device designed to pull or haul heavy loads. It is commonly used in various industries, including construction, mining, maritime, and material handling. The winch utilises a drum and a cable or rope to exert pulling force and move objects horizontally or vertically.

Choosing the right hauling winch depends on several factors, including the weight of the loads you need to move, the distance to be covered, the required line speed, and the specific environmental conditions. Consulting with winch manufacturers or experts can help you assess your needs and select the appropriate winch model and specifications.

Operating a hauling winch safely involves wearing proper personal protective equipment (PPE), conducting pre-operational inspections, ensuring clear communication with other personnel involved, following safe operating procedures, and being aware of emergency shutdown protocols. It is important to receive adequate training and adhere to industry safety guidelines.

Yes, many winch manufacturers offer customization options to tailor the winch to your specific application requirements. Customisation may include line pull capacities, line speeds, drive motor types (electric or hydraulic), control systems, and additional features. Consulting with the manufacturer can help determine the extent of customisation available.

Regular maintenance is essential to ensure your hauling winch’s ongoing performance and longevity. The frequency of maintenance depends on factors such as usage intensity, operating conditions, and manufacturer recommendations. Implementing a proactive maintenance schedule and conducting routine inspections can help promptly identify and address any potential issues.

Yes, hauling winches can be designed to handle a wide range of loads, from heavy machinery to delicate materials. By selecting the appropriate winch model, and line pull capacity and utilising proper rigging techniques, you can safely handle and transport various types of loads with precision and care.

Yes, hauling winches are commonly used in marine applications. They are designed to withstand harsh marine conditions, such as saltwater exposure and corrosion. Choosing winches specifically designed for marine use and following proper maintenance procedures to ensure their durability and longevity in such environments is important.

Electric winches are powered by electricity and offer precise control, ease of use, and lower maintenance requirements. On the other hand, hydraulic winches use hydraulic power to generate pulling force and are known for their robust power and ability to handle heavy loads. The choice between electric and hydraulic winches depends on factors such as load capacity, operational requirements, and available power sources.

Yes, hauling winches can be used in confined spaces, provided that proper safety precautions are taken. It is important to assess the space, ensure proper ventilation, and have clear communication and emergency plans in place. Consult with safety experts to ensure compliance with regulations and guidelines specific to confined space operations.

Yes, many equipment rental companies offer hauling winches for short-term or project-specific use. Renting a winch can be cost-effective when you have temporary needs or limited budgets. It is essential to communicate your requirements to the rental company to ensure that the provided winch meets your specific needs and is in good working condition.

Neumann Equipment offers top-of-the-line hauling winches designed to meet your every need. Our hauling winches are made with the highest-quality materials and are built to withstand even the most demanding applications. And if you can't find exactly what you're looking for, we can custom-design and manufacture hauling winches with up to a 200-tonne line pull - no job is too big or too small for us.

Our mission is to provide practical and innovative solutions to our clients, and we have successfully done so for customers worldwide. With our years of experience and commitment to quality, you can trust that our hauling winches will meet and exceed your expectations. Let us help you find the perfect hauling winch for your needs - contact us today!

At Neumann Equipment, we take great pride in designing and engineering our hauling winch units in-house using our cutting-edge FEA computer modelling software. All units are rigorously tested to ensure they meet the latest marine and industry standards, giving you peace of mind regarding reliability and safety.

When you choose a winch from Neumann Equipment, you can trust our commitment to quality. Our internal Quality Assurance Systems comply with AS/NZS ISO 9001:2008 standards, ensuring that your winch is designed and manufactured to the highest level of precision and performance.

Our state-of-the-art facility in Currumbin, on the stunning Gold Coast in Queensland, is where we design and manufacture all our equipment. You can rest assured that you’re purchasing a winch built to withstand the harshest Australian conditions.

Our range of winches is suitable for various industrial and mining applications. With many years of experience behind us, our Sales, Service and Spare Parts teams are ready to assist with all your hauling winch requirements. Don’t settle for anything less than the best – choose Neumann Equipment for all your winch needs.

Articles about Hauling Winches:

When it comes to hauling winches, one name stands out among the rest: Neumann Equipment. Neumann Equipment has been designing and manufacturing high-quality industrial winches for over 50 years. Their hauling winches are renowned for their reliability, safety, and efficiency. This essay will examine the hauling winches designed and manufactured by Neumann Equipment.

History:

Neumann Equipment was founded in Australia in 1965. Since then, the company has grown into a global leader in designing and manufacturing industrial winches, hoists, and anchor windlasses. They have provided customized solutions for clients across various industries, including mining, construction, marine, and oil and gas.

Design:

Neumann Equipment’s hauling winches are designed to meet the specific needs of their clients. They offer various winches, from small portable winches to large-scale offshore winches. They can provide multiple power options, including hydraulic, electric, and diesel. They also offer multiple configurations for wire, chain, or synthetic rope.

Safety:

Safety is a top priority for Neumann Equipment, and their hauling winches are designed with safety features to protect the operator and equipment. Their winches are equipped with emergency stop buttons, automatic load monitoring, and limit switches to prevent overloading. They also offer advanced safety features, such as remote monitoring and control capabilities, to improve overall safety.

Efficiency:

Neumann Equipment’s hauling winches are designed to be efficient and easy to use. They offer features like variable speed control, automatic spooling, and wireless remote controls to improve productivity for the operator. Their winches are also equipped with durable components to provide reliable, trouble-free performance over the long term.

Customization:

Neumann Equipment understands that each client’s needs are unique, and they offer a range of customization options to meet those needs. They can provide customized drum sizes, wire rope types, and power options. They also offer a variety of accessories, including anchors, fairleads, and cable clamps, to meet specific requirements.

Support:

Neumann Equipment is committed to providing exceptional customer service and support. They offer comprehensive support for their hauling winches, including installation, training, and maintenance services. Their team of experts can also provide customized solutions to meet specific needs.

Conclusion:

Neumann Equipment’s hauling winches are designed and manufactured to meet the needs of various industries. Their commitment to safety, reliability, and efficiency has made them a trusted partner for clients across the globe. With their expertise and personalized approach, Neumann Equipment is poised to continue leading the way in hauling winches for many years to come.

Hauling winches are essential for various industries and applications, including commercial, industrial, and marine. They are used for various tasks, from conveyor belt replacements to dredge recovery and slipway winching. Neumann Equipment is a leading manufacturer of hauling winches, providing high-quality and reliable equipment to meet the demands of the most challenging conditions. In this essay, we will explore in detail the design, manufacturing, and applications of Neumann Equipment hauling winches.

Design and Engineering The design and engineering of all Neumann Equipment hauling winches in-house by qualified mechanical engineers using Finite Element Analysis (FEA) computer modelling software. This process ensures that the hauling winches are designed to meet the highest standards and comply with all relevant specifications and marine and industry standards. The FEA software allows for detailed analysis and simulation of various stresses and loads on the equipment, resulting in a design optimized for performance and longevity.

Manufacturing and Testing All Neumann Equipment hauling winches are manufactured and tested to meet the applicable marine and industry standards. The equipment is built tough and designed to last, using high-quality components and materials. Neumann Equipment’s internal Quality Assurance Systems fully comply with AS/NZS ISO 9001:2008, ensuring the equipment is of the highest quality and reliability. All of Neumann Equipment’s hauling winches are manufactured at the company’s facility in Currumbin, on the Gold Coast, Queensland, Australia.

Custom Design Neumann Equipment can custom-design and manufacture hauling winches to meet the specific needs of its clients. The company has provided an extensive range of practical solutions for many clients around the globe, ranging from small-scale applications to large-scale projects. Neumann Equipment hauling winches can have up to 200-tonne line pull, making them suitable for a wide range of applications.

Applications Neumann Equipment hauling winches are designed to meet the demands of commercial, industrial, and marine applications. They are used in a range of tasks, including:

Conveyor Belt Replacements Hauling winches are used to pull conveyor belts into position during replacements, ensuring that the new belt is properly aligned and tensioned. This task requires a winch to handle heavy loads and precisely control the pulling force.

Cable Hauling Hauling winches are used to pull cables through conduits, trenches, or over long distances. This task requires a winch that can handle the weight and stiffness of the cable while providing precise control over the pulling force.

Low Loader Recovery Winches Hauling winches are used to recover low loaders that have become bogged down or stuck. This task requires a winch that can handle the weight of the low loader and provide enough pulling force to extract it from the rugged terrain.

Dredge Recovery Hauling winches are used to recover dredging equipment that has become stuck or bogged down in sediment. This task requires a winch that can handle the weight of the equipment and provide enough pulling force to extract it from the sediment.

Slipway Winch Hauling winches are used to move boats on and off a slipway for maintenance or repairs. This task requires a winch that can handle the weight of the boat and provide precise control over the pulling force to ensure the safety of the boat and the workers.

In conclusion, Neumann Equipment hauling winches are designed and manufactured to meet the demands of the most challenging conditions. Their custom-design capabilities, use of high-quality components and materials and adherence to industry standards make them reliable and durable.

Elevate Your Operations with the Right Hauling Winch – Power, Precision, and Performance Combined!

Enhancing Industrial Operations with the Right Hauling Winch

In the fast-paced world of industrial operations, efficiency and reliability are paramount. The hauling winch is an essential piece of equipment that plays a crucial role in many applications. From construction and mining to offshore operations and material handling, selecting the right hauling winch can significantly impact productivity and safety. In this article, we will explore the importance of choosing the perfect hauling winch for your specific industrial application and the key factors to consider.

Understanding the Unique Requirements of Your Industrial Application

Every industrial application is unique, requiring careful consideration when selecting a hauling winch. Factors such as load capacity, line speed, environmental conditions, and safety requirements must be considered. By thoroughly understanding the specific demands of your operation, you can ensure the chosen winch is ideally suited to meet your needs.

Power and Line Pull Capacity: Matching the Winch to the Task

One of the primary considerations when choosing a hauling winch is its power and line pull capacity. This determines the maximum weight the winch can safely handle. Selecting a winch with an appropriate line pull capacity that matches or exceeds the weight of the loads you will be moving is crucial. Overloading a winch can result in decreased performance, premature wear, and even safety hazards.

Speed and Efficiency: Selecting the Optimal Hauling Line Speed

Another critical factor to consider is the hauling line speed. The line speed directly impacts the efficiency of your operations. Choosing a winch with the optimal line speed ensures swift and smooth movement of materials or equipment, saving valuable time and resources. However, it is essential to strike the right balance, as excessively high line speeds may compromise safety and control.

Electric or Hydraulic: Choosing the Ideal Drive Motor Type

When it comes to the drive motor type, two popular options are electric and hydraulic. Electric winches offer precise control, ease of use, and reduced maintenance requirements. On the other hand, hydraulic winches provide robust power, making them suitable for heavy-duty applications. Carefully evaluate the specific demands of your industrial operation to determine the most suitable drive motor type for your hauling winch.

Gearboxes and Reduction Styles: Customising the Winch for Maximum Output

A hauling winch’s gearbox and reduction style play a crucial role in its performance. Different reduction styles offer varying torque and speed levels, allowing you to customise the winch to maximise output and efficiency. Selecting the right gearbox and reduction style ensures optimal performance, making your hauling winch a valuable asset in your industrial operations.

Safety and Control: Electrical and Hydraulic Control Systems

Safety should always be a top priority in industrial operations. Choosing a hauling winch with reliable electrical or hydraulic control systems enhances safety and control. These systems give operators precise control over the winch’s movements, allowing for smooth and safe operation. Features such as emergency stop buttons, overload protection, and advanced monitoring systems further enhance safety measures, reducing the risk of accidents and equipment damage.

Robust Construction: Quality Components for Durability and Longevity

Industrial environments can be harsh, subjecting equipment to extreme conditions. Choosing a hauling winch constructed with high-quality components and materials that can withstand these challenges is vital. Features such as fully sealed self-aligning bearings, durable drum shells, and robust frames ensure the winch can endure heavy loads, constant use, and exposure to elements, guaranteeing its durability and longevity.

Customisation and Adaptability: Tailoring Hauling Winches to Your Needs

No two industrial applications are exactly alike, and off-the-shelf solutions may not always meet your specific requirements. Opting for a manufacturer offering customisation options allows you to tailor the hauling winch to your needs. From line pull capacity and line speed to control systems and additional features, the ability to customise ensures the winch integrates seamlessly into your operations, maximising efficiency and productivity.

Conclusion: Elevating Industrial Operations with the Perfect Hauling Winch

Choosing the right hauling winch is paramount to achieving optimal efficiency, productivity, and safety in industrial operations. By thoroughly understanding the unique requirements of your application and considering factors such as power, speed, drive motor type, control systems, construction quality, and customisation options, you can select a hauling winch that perfectly aligns with your needs. Remember, the right hauling winch is an investment that pays off in increased efficiency, enhanced safety, and long-term reliability, allowing your industrial operations to reach new heights of success.

In conclusion, the importance of selecting the right hauling winch for your industrial application cannot be overstated. It directly impacts the efficiency, productivity, and safety of your operations. You can ensure that the chosen winch perfectly matches your needs by carefully evaluating factors such as power, line pull capacity, line speed, drive motor type, control systems, construction quality, and customisation options.

Investing in a high-quality hauling winch tailored to your application will unleash the full potential of your industrial operations. It will provide you with the power, precision, and performance required to handle heavy loads, maneuver materials efficiently, and maintain a safe working environment. Whether in construction, mining, offshore operations, or material handling, the right hauling winch will elevate your operations to new levels of success.

Remember, when choosing a hauling winch, prioritise reliability, durability, and safety. Look for reputable manufacturers who have a proven track record of delivering high-quality winches that meet industry standards. Consult with experts to assess your needs accurately and guide you in selecting the most suitable winch for your specific application.

So, don’t underestimate the impact of the right hauling winch. It can be the game-changer that optimises your industrial processes, enhances productivity, and ensures the success of your operations. Choose wisely, invest in the perfect hauling winch, and unlock the full potential of your industrial endeavours.

Pushing the Boundaries of Winch Design with Finite Element Analysis

In the realm of hauling winch design, precision and robustness are paramount. The ability to withstand extreme loads and endure harsh operating conditions while maintaining optimal performance requires a meticulous approach. Finite Element Analysis (FEA) emerges as an indispensable tool, revolutionising the design process and ensuring the creation of hauling winches that possess unmatched strength and reliability. In this article, we delve into the role of Finite Element Analysis in designing robust hauling winches that exceed expectations.

Understanding Finite Element Analysis and Its Significance in Winch Design

Finite Element Analysis is a computational technique that enables engineers to simulate the behaviour of complex structures and components under various loading conditions. It involves breaking down a winch into finite elements and analysing their interactions to predict its response to external forces. By applying mathematical models and numerical algorithms, FEA provides insights into stress distribution, deformations, and performance characteristics that aid in optimising design parameters.

Stress Analysis: Ensuring Structural Integrity under Extreme Loads

One of the primary applications of Finite Element Analysis in winch design is stress analysis. By subjecting the winch model to simulated loads, FEA enables engineers to identify areas of high-stress concentration. This analysis helps in optimising the winch’s structural design, ensuring that critical components can withstand the expected loads without compromising their integrity. By identifying potential failure points, designers can make informed decisions to reinforce weak areas, enhancing the winch’s overall robustness.

Optimising Component Design: Enhancing Performance and Durability

FEA allows engineers to evaluate individual components of the hauling winch, such as gears, bearings, and drums, in isolation and conjunction with other parts. Through this analysis, they can assess factors such as material selection, geometry, and load distribution to optimise the performance and durability of each component. By fine-tuning these elements, the overall efficiency and lifespan of the winch can be significantly improved, leading to enhanced reliability and reduced maintenance requirements.

Fatigue Analysis: Predicting Winch Lifespan and Reliability

Fatigue analysis is a critical aspect of winch design, as it predicts the lifespan and reliability of the equipment under cyclic loading. By subjecting the winch to repeated loading and unloading conditions, FEA can simulate fatigue damage accumulation over time. Engineers can identify potential fatigue failure points and make design modifications to mitigate these risks. By ensuring that the winch can withstand the expected operational lifespan without succumbing to fatigue, FEA helps in delivering winches with extended service life and enhanced reliability.

Fine-Tuning Efficiency: Evaluating Mechanical Systems and Energy Consumption

The efficiency of a hauling winch directly impacts operational costs and energy consumption. FEA allows engineers to evaluate the mechanical systems within the winch, such as gear trains and power transmission components, to optimise energy efficiency. By analysing the interactions between different elements, engineers can identify areas of energy loss, friction, and inefficiencies. This analysis enables them to make design adjustments and select the most efficient configurations, ultimately reducing energy consumption and improving overall winch performance.

Safety Assurance: Verifying Performance in Diverse Operating Conditions

Safety is of utmost importance in winch design, especially considering the demanding environments in which they operate. To assess the winch’s performance and safety margins, FEA enables engineers to simulate various operating conditions, such as extreme temperatures, vibrations, and dynamic loads. By verifying that the winch can operate reliably under different scenarios, FEA helps ensure the safety of operators, equipment, and surrounding infrastructure.

Seamless Integration: Simulating Winch Behavior within Complex Environments

Hauling winches are often part of larger systems or installations, requiring seamless integration into complex environments. FEA facilitates the simulation of winch behaviour within these intricate setups, allowing engineers to understand interactions with other components or structures. This analysis aids in identifying potential clashes, interferences, or limitations that could impact the winch’s functionality or surrounding equipment, enabling design adjustments for seamless integration.

Collaborative Design: Enhancing Communication and Iterative Improvement

FEA promotes collaborative design by visually representing the winch’s behaviour and performance characteristics. It enables engineers from different disciplines to share and analyse data, fostering effective communication and interdisciplinary decision-making. This collaborative approach facilitates iterative improvement, allowing for continuous winch design refinement based on multiple experts’ feedback and insights.

Conclusion: Elevating Winch Design with Finite Element Analysis – Unleashing Unmatched Robustness and Performance

Finite Element Analysis has revolutionised winch design by offering unparalleled insights into the behaviour and performance of hauling winches. Through stress analysis, component optimisation, fatigue assessment, efficiency fine-tuning, safety verification, and seamless integration, FEA ensures the creation of robust winches that can withstand extreme loads, endure challenging conditions, and deliver exceptional performance. Leveraging the power of precision, Finite Element Analysis empowers engineers to push the boundaries of winch design, unlocking unmatched robustness and reliability.

By harnessing the potential of Finite Element Analysis, manufacturers can confidently engineer hauling winches that exceed expectations, provide long-term durability, and contribute to enhanced productivity and safety in a variety of industrial applications. With FEA as an integral part of the design process, the future of hauling winches promises continued strength, efficiency, and performance advancements.

Introduction: The Significance of Safety in Hauling Winch Operations

Safety is of paramount importance when operating hauling winches. These powerful machines are designed to handle heavy loads and work in challenging environments. It is crucial to implement essential safety measures to ensure the well-being of operators, personnel, and the equipment itself. This article explores the key safety considerations and steps to prioritise when operating hauling winches.

Comprehensive Training: Equipping Operators with Proper Knowledge and Skills

Proper training is essential for anyone operating a hauling winch. Operators should receive comprehensive training that covers the fundamentals of winch operation, safety protocols, and emergency procedures. Training should include hands-on practice and theoretical knowledge to ensure operators have the necessary skills to operate the winch safely and efficiently.

Pre-Operational Inspections: Ensuring Equipment Readiness and Functionality

Before operating a hauling winch, conducting pre-operational inspections is vital. Inspections should thoroughly assess the winch’s components, such as cables, drums, controls, and safety mechanisms. Any signs of wear, damage, or malfunctions should be addressed promptly to prevent accidents and ensure the winch’s readiness for safe operation.

Load Assessment and Rigging: Calculating and Securing the Weight Safely

Accurate load assessment and proper rigging are critical for safe hauling winch operations. Operators must determine the weight and characteristics of the load being moved and select appropriate rigging equipment accordingly. Adequate securing of the load with appropriate slings, hooks, or other rigging devices is essential to prevent accidents and ensure stability during transportation.

Clear Communication: Establishing Effective Communication Channels

Effective communication is crucial when operating hauling winches. Clear communication channels must be established between operators, signalpersons, and other personnel involved in the operation. Hand signals, two-way radios, or other communication devices should be utilised to ensure everyone is on the same page and can promptly communicate any concerns or changes during the operation.

Personal Protective Equipment (PPE): Essential Gear for Operator Safety

Operators must always wear appropriate personal protective equipment (PPE) when operating hauling winches. This includes safety helmets, protective eyewear, gloves, and sturdy footwear. Additional PPE, such as high-visibility vests, hearing protection, and respiratory masks, may be necessary depending on the specific application and environment. PPE helps minimise the risk of injuries and safeguards the well-being of operators.

Safe Operating Procedures: Following Industry Best Practices

Adhering to safe operating procedures is vital for preventing accidents and ensuring the overall safety of hauling winch operations. Operators should familiarise themselves with industry best practices and follow established guidelines and safety protocols. This includes proper winch operation techniques, load capacity limits, and safe working distances from the equipment. Compliance with these procedures is essential for accident prevention and maintaining a safe work environment.

Regular Maintenance and Inspections: Ensuring Winch Integrity Over Time

Regular maintenance and inspections are crucial to ensure the continued integrity and safe operation of hauling winches. Implementing a proactive maintenance schedule, including routine inspections, lubrication, and component checks, helps identify any potential issues or signs of wear before they develop into major problems. Regular maintenance maximises the winch’s performance and reduces the risk of equipment failure during operation.

Emergency Preparedness: Being Ready for Unexpected Situations

Even with meticulous planning and adherence to safety measures, unexpected situations can arise during hauling winch operations. Operators must be prepared for emergencies and equipped with the knowledge of appropriate response procedures. This includes understanding emergency shutdown protocols, fire prevention measures, and evacuation plans. Regular drills and training exercises help ensure operators can act swiftly and effectively in critical situations.

Conclusion: Commitment to Safety – Safeguarding Lives and Enhancing Operations

Safety should always be the top priority when operating hauling winches. Operators can minimise risks, prevent accidents, and safeguard lives by implementing essential safety measures. Comprehensive training, pre-operational inspections, load assessment, clear communication, proper PPE, adherence to safe operating procedures, regular maintenance, and emergency preparedness are all vital components of a robust safety program.

Prioritising safety not only protects personnel but also enhances overall operations. By fostering a safety-conscious culture, organisations can create an environment where everyone is actively involved in maintaining a safe workplace. Regular training, ongoing communication, and continuous improvement efforts contribute to a safer and more efficient hauling winch operation.

Remember, safety is a collective responsibility. Every individual involved in hauling winch operations plays a crucial role in ensuring the well-being of themselves and others. Committing to safety and incorporating these essential safety measures can create a workplace where accidents are minimised, productivity thrives, and operations run smoothly and securely.