You must use the correct sized wire rope on your Neumann Equipment winch. The diameter of the wire is generally specified for each winch application. Consult your Operation and Maintenance Manual provided with your winch, or call our helpful staff for assistance.

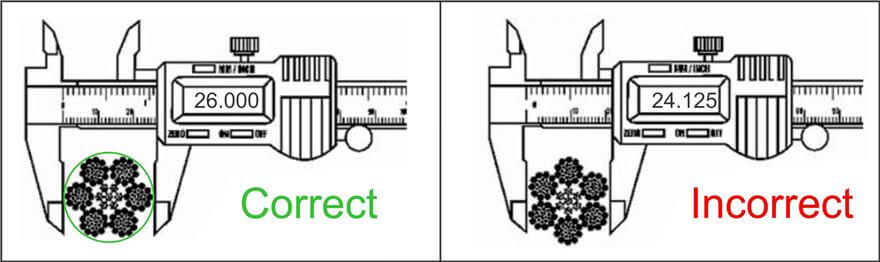

Measuring the Diameter of Wire Rope

Its diameter most often describes wire rope. You can determine the rope’s diameter by measuring the circle that touches the extreme outer limits of the strands of rope, as shown in the diagram below. You can measure the diameter using a pair of parallel-jawed callipers or a machinist’s calliper square, as shown below. You could make a mistake by measuring the smaller dimension.

Unreeling and Uncoiling your Wire Rope for use on your Winch

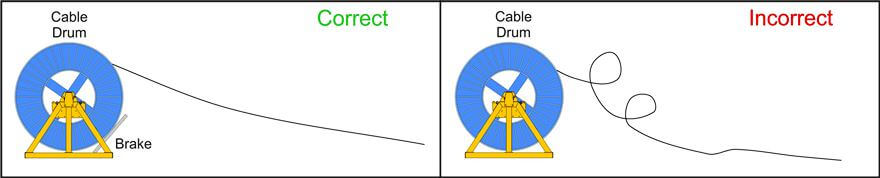

Unreeling Wire Rope from a Cable Drum – To unreel wire rope from a heavy wire rope drum, place a shaft through the centre and jack up the reel far enough to clear the floor and revolve easily. We have several sizes of Cable Drum Stands. You can use that for this purpose. This is a two-person operation; the first person takes the rope’s end and walks away from the reel, taking the wire rope off the top of the reel. The second person needs to control the speed of the turning cable drum by holding a wood block against the flange as a brake (or by using the brake mechanism on the Cable Drum Stands). You must take care to stop slack rope developing on the reel, which can cause kinks in the wire rope. Lightweight cable drums can be unreeled using a vertical shaft, but You must take the same care to keep the wire rope taut.

Care must be taken when unreeling wire rope to avoid throwing off turns or spiral in which kinks could occur. You should never handle the wire rope in a way that twists or unlays the wire rope.

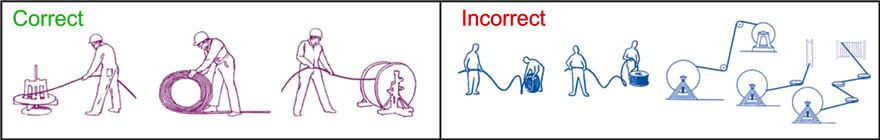

Uncoiling a Wire Rope – There is only one correct way to uncoil wire rope. Again, it is a two-person job, whereby the first person holds the end of the rope while the second person rolls the coil along the floor, backing away. The rope must be allowed to uncoil naturally with the lay, without spiralling or twisting. Always uncoil wire rope, as shown below.

Never uncoil wire rope by pulling coils off a coil that is laid flat on the ground. Doing this will create spirals and likely kinking of the rope. Torsions are put into the rope by every loop pulled off, and the rope becomes twisted and unmanageable. Please note that You cannot uncoil wire rope like hemp rope. Pulling one end through the middle of the coil will only result in kinking.

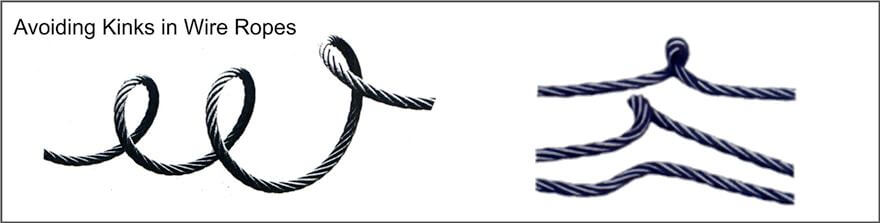

Avoiding Kinks in Wire Ropes – It is vital to avoid kinking your wire rope. Kinks are places where the rope has been unintentionally bent to a permanent set. This often happens when loops are pulled through by tension on the rope until the diameter of the loop is only a few centimetres. They can also be caused by bending a rope around a sheave having too severe a radius. Wires in the strands at the kink are permanently damaged and will not give normal service, even after apparent “re-straightening.”

Winding Wire Rope onto a Winch Drum from a Cable Drum

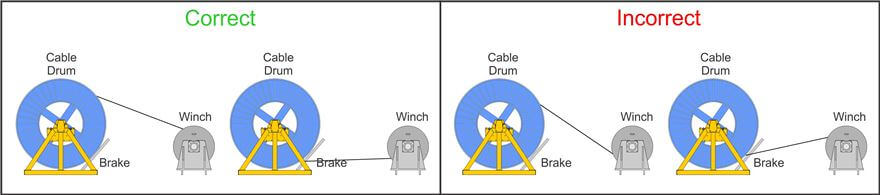

When you are winding new wire rope unto your winch drum, it should bend in the way you originally winded it. This will avoid causing a reverse bend in the rope. As shown below, always wind wire rope from the top of one reel onto the top of the other. It is also acceptable to re-reeling from the bottom of one reel to the bottom of another. Re-reeling may also be done with reels having their shafts vertical, but you must take extreme care to ensure that the rope always remains taut. It should never be allowed to drop below the lower flange of the reel. You may also roll a reel resting on the floor with its axis horizontal along the floor to unreel the rope.

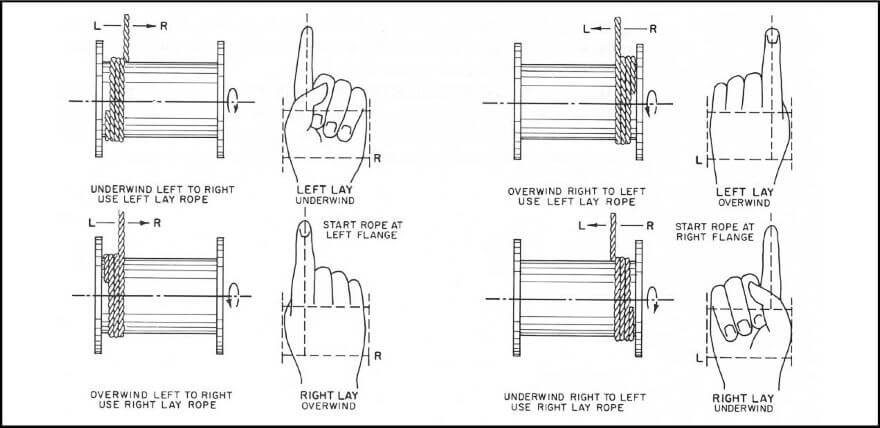

Wire rope should be attached at the correct location on a flat or smooth-faced drum so that the rope will spool evenly, with the turns lying snugly against each other in even layers. If wire rope is wound on a smooth-face drum in the wrong direction, the first layer of rope turns will tend to spread apart on the drum. This results in the second layer of rope wedging between the open coils, crushing and flattening the rope as successive layers are spooled.

A simple method of determining how you should start a wire rope on a drum is shown above. The observer stands behind the drum, with the rope coming towards him. Using the right hand for right-lay wire rope and the left hand for left lay wire rope, the clenched fist denotes the drum, the extended index finger the oncoming rope.

If you have any questions or concerns regarding installing new wire rope to your Neumann Equipment Winch, don’t hesitate to get in touch with our experienced staff on 07 5589 9746.